Alloy 601

About Alloy 601

What is Alloy 601?

Alloy 601 also referred to as the UNS N06601 and W.Nr. 2.4851 alloy.

This alloy is a general-purpose engineering material for applications that require resistance to heat and corrosion.

The alloy also has good resistance to aqueous corrosion, has high mechanical strength, and is readily formed, machined and welded.

The composition is a facecentered- cubic solid solution with a high degree of metallurgical stability.

The alloy’s nickel base, in conjunction with substantial chromium content, provides resistance to many corrosive media and hightemperature environments. Oxidation resistance is further enhanced by the aluminum content.

The properties of alloy 601 make it a material of broad utility in such fields as thermal processing, chemical processing, pollution control, aerospace, and power generation.

Chemical-processing applications for alloy 601 include process heaters, condenser tubes in sour-water strippers, and insulating cans in ammonia reformers. The alloy is also used for combustor components and catalyst grid supports in equipment for nitric acid production.

In petrochemical processing, the alloy is used for catalyst regenerators and air preheaters in the manufacture of high-density polyethylene.

The 601 alloy is also used for jet-engine igniters and for combustion-can liners, diffuser assembles, and containment rings in gas turbines for aircraft, industrial, and vehicular applications.

Alloy 601 Standards

ASTM B167

-Seamless Pipe & Tube

ASTM B516

-Welded Pipe & Tube

ASTM B166

-Rod, Bar and Wire

ASTM B168

-Plate, Sheet, Strip & Foil

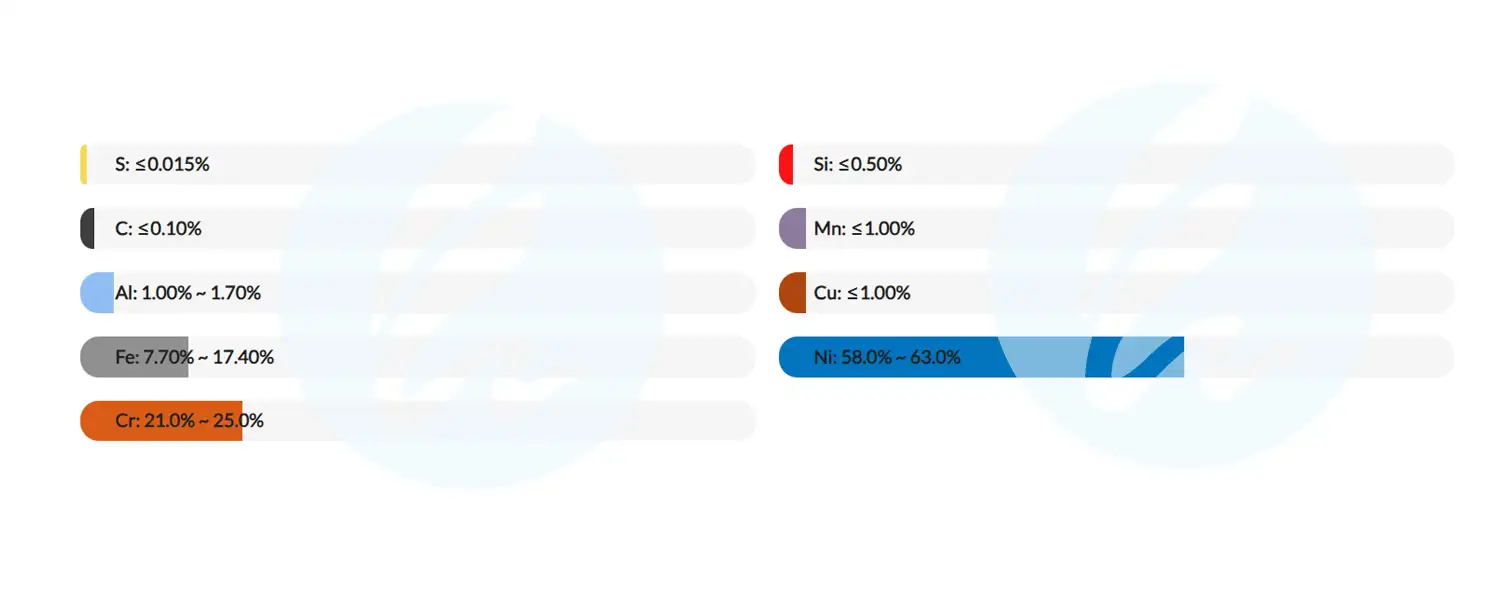

Alloy 601 Chemical Composition

Alloy 601 Data Sheet

Alloy 601 Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Alloy 601 | 2.4851 | N06601 | – | – | – | – | – | – |

Alloy 601 Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.11 g/cm3 | 1411 °C (2571 °F) | 550-1310Mpa | 205-1205Mpa | 70% – 2% |

Alloy 601 Physical Properties

| Melting Range | Specific Heat, 20°C (J/(g.K)) | Magnetic Permeability (20°C) | Thermal Conductivity, 20°C (W/(m.K)) | Curie Temperature (°C) |

| 1411 °C (2571 °F) | 448 | <1.003 | 11.2 | -196 |

Alloy 601 Applications

Alloy 601 Related Resources

Are you looking forward to having a plan or coming up with an idea to buy quality nickel based alloys products from global leading suppliers? If yes, here you’ve come to the right place. There are many nickel based alloys manufacturers worldwide, but we discuss the top 10 trustworthy suppliers of nickel based alloys here. …

Top 10 Trustworthy Suppliers for Nickel Based Alloys Read More »

Get A Free Quote Now

Got a question? Contact our team!

Looking For a Trust Nickel Alloys & Stainless Steel Manufacturer?

At SEATHER, we are experts in the field of alloys manufacturing. As such, we offer a variety of services to ensure your project is formed to your exact requirements.