Alloy 80A

About Alloy 80A

What is Alloy 80A?

Alloy 80A also referred to as the UNS N07080/W.Nr. 2.4952 alloy.

It is a wrought, age-hardenable nickel-chromium alloy, strengthened by additions of titanium, aluminum and carbon, developed for service at temperatures up to 815°C (1500°F)

Alloy 80A is widely used in gas turbine components (blades, rings and discs), bolts, nuclear boiler tube supports, die casting inserts and cores, and automobile exhaust valves.

Alloy 80A is available in the form of sheet, round bar, flat bar, forging, hexagon, wire, plate and extruded section.

Alloy 80A Standards

BS HR 401

-Seamless Pipe & Tube

BS HR 201

-Plate, Sheet, Strip & Foil

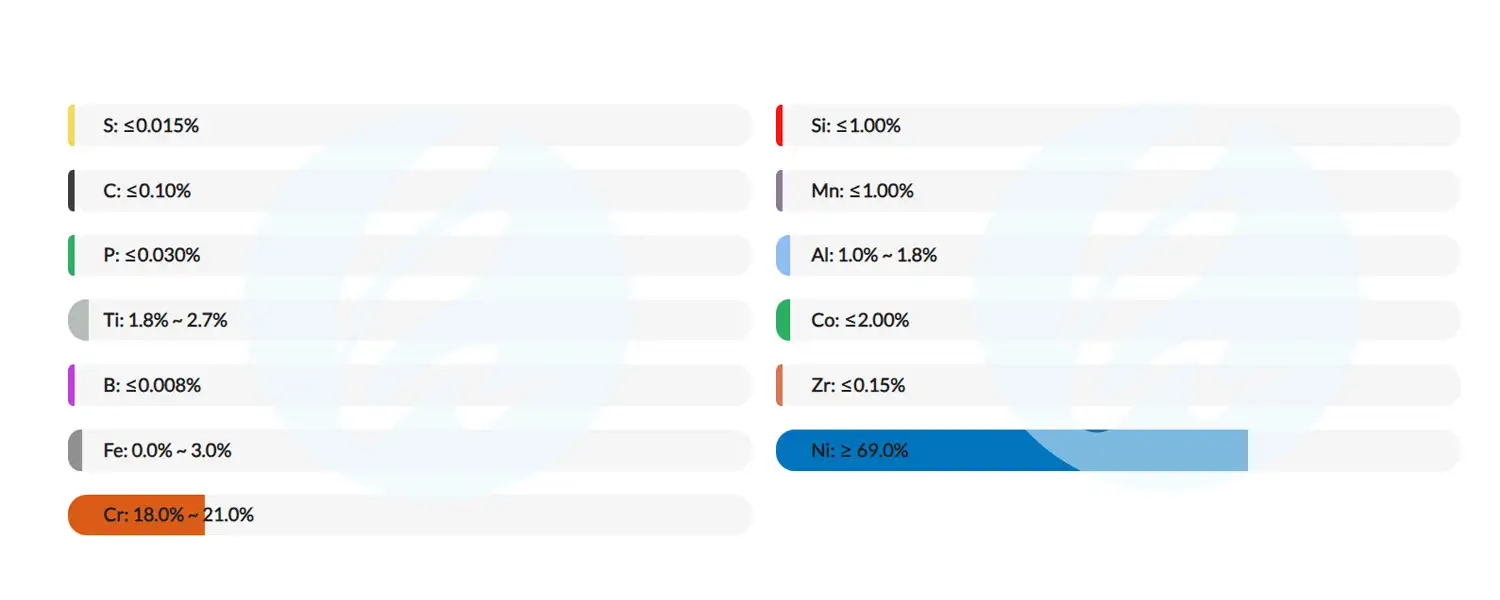

Alloy 80A Chemical Composition

Alloy 80A Data Sheet

Alloy 80A Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Alloy 80A | 2.4952/2.4631 | N07080 | – | – | – | – | – | – |

Alloy 80A Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.19 g/cm3 | 1365°C (2490°F) | 1250Mpa | 780Mpa | 30% |

Alloy 80A Applications

Alloy 80A Related Resources

Are you looking forward to having a plan or coming up with an idea to buy quality nickel based alloys products from global leading suppliers? If yes, here you’ve come to the right place. There are many nickel based alloys manufacturers worldwide, but we discuss the top 10 trustworthy suppliers of nickel based alloys here. …

Top 10 Trustworthy Suppliers for Nickel Based Alloys Read More »

Get A Free Quote Now

Got a question? Contact our team!

Looking For a Trust Nickel Alloys & Stainless Steel Manufacturer?

At SEATHER, we are experts in the field of alloys manufacturing. As such, we offer a variety of services to ensure your project is formed to your exact requirements.