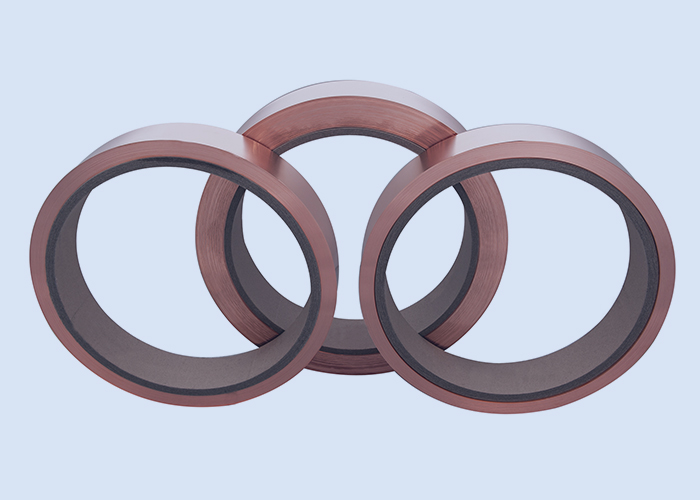

Copper Foil Strip For Transformer Winding

Copper foil strip is often used as low voltage side winding in dry power transformer.

The copper foil for transformer range from 0.1 mm to 3.0 mm thickness and 5 mm to 1200 mm width.

The foil strip made of high quality oxygen-free copper mother coil, which has good conductivity, has small contact resistance and low temperature rise, and can effectively reduce power loss and ensure long-term stable operation of the transformer.

Insulated foils are used in dry-type transformers and small transformers, where they are wound together with insulating materials.

| Product Name | Copper foil for transformer winding |

| Grades | T2/C1100/C11000/Cu-ETP |

| Temper | Soft |

| Thickness | 0.1mm-3.0mm |

| Width | 5mm-1200mm |

| Edge | Deburred/Round |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø 150mm, Ø300mm, Ø400mm, Ø500mm paper core, special internal diameter core and without paper core on special request |

| Surface Treatment | Mill finish, the foil strip has a smooth surface, free from scratches and impurities |

Electrical Conductivity (20℃)(IACS) | ≥99.80% |

| Applications | Transformer winding |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 7-10 working days |

| MOQ | 500 Kgs |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of copper foil is available |

| Remark | C1100/C11000/Cu-ETP copper foil strip can be customized |

Copper Foil Strip For Transformer Winding Grades

Copper foil is one of the main materials for producing transformers. As an important electronic device, the transformer will convert one voltage to another voltage. The two coils are called primary coil and secondary coil.

Copper foils strips for transformers winding grades are as follows:

- ETP Grade (Electrolytic Tough Pitch)

- T2 Grade (China GB/T Standard)

- C1100, C11000, etc.

Copper Foil Strip For Transformer Winding Chemical Composition

| China Grade | Spec. | Range | %Cu+Ag | %Sn | %Zn | %Pb | %O | %Others |

| T2 | GB/T | Min. | 99.9 | Balance | ||||

| Max. | 0.002 | 0.005 | 0.005 | 0.04 | Balance |

Copper Foil Strip For Transformer Winding Properties

GB/T | ASTM | DIN | ITALY | Tensile Strength Rm | Temper (Annealed) | Vickers Hardness-Soft | Elongation(%) |

T2 | ETP/C11000 | E-Cu 58 | CU-ETP | 195-220 | O | 40-65 | ≥38 |

Your Reliable Copper Foil Strip For Transformer Winding Manufacturer In China

Copper Foil Strip For Transformer Winding: The Ultimate Guide

When you choose to buy quality copper foil strip for transformer winding, there have some important points we need to know before we get started.

What are copper foil strip for transformer winding?

Copper foil strip is often used as low voltage side winding in dry power transformer.

The copper foil for transformer range from 0.1 mm to 3.0 mm thickness and 5 mm to 1200 mm width.

The foil strip made of high quality oxygen-free copper mother coil, which has good conductivity, has small contact resistance and low temperature rise, and can effectively reduce power loss and ensure long-term stable operation of the transformer.

Insulated foils are used in dry-type transformers and small transformers, where they are wound together with insulating materials.

What are the applications that copper foil strip for transformer winding can be used?

Copper foil strip for transformer winding has several applications in the electrical and transformer industry.

Some of the key applications include:

- Power Transformers: Copper foil strip is extensively used in the windings of power transformers. Power transformers are crucial components of electrical power transmission and distribution systems, and the copper foil strip ensures efficient power transfer, high conductivity, and low electrical losses.

- Distribution Transformers: Distribution transformers, which are responsible for stepping down the voltage for distribution to end-users, also make use of copper foil strip in their windings. Copper’s excellent conductivity and high mechanical strength make it an ideal choice for these transformers.

- Instrument Transformers: Copper foil strip is used in the windings of instrument transformers such as current transformers and voltage transformers. These transformers are employed for measuring and monitoring electrical parameters in various applications, including protection systems, metering, and control.

- Inductors and Reactors: Copper foil strip is utilized in the windings of inductors and reactors, which are essential components in electrical circuits for applications such as filtering, energy storage, and magnetic field generation.

- High-Frequency Transformers: Copper foil strip finds application in high-frequency transformers used in electronic devices, telecommunications, and power electronics. The excellent electrical conductivity of copper enables efficient power transfer in these high-frequency applications.

These are some of the primary applications where copper foil strip for transformer winding is utilized. Its exceptional electrical conductivity, mechanical strength, and reliability make it a preferred choice for various transformer and electrical applications.

Features of copper foil strip for transformer winding

Copper foil strip for transformer winding possesses several key features that make it an ideal choice for transformer applications.

Some of these features include:

Excellent Electrical Conductivity: Copper is renowned for its high electrical conductivity, making it an optimal material for transformer windings. The low resistivity of copper foil strip ensures efficient power transfer and minimizes energy losses in the transformer.

High Mechanical Strength: Copper foil strip exhibits high mechanical strength, allowing it to withstand the stresses and forces experienced during the transformer winding process and operation. This strength helps maintain the integrity and stability of the winding structure.

Good Thermal Conductivity: Copper has excellent thermal conductivity, which facilitates efficient heat dissipation in transformers. Proper heat management is crucial for the reliable and optimal performance of transformers.

Ductility and Formability: Copper foil strip is highly ductile and can be easily formed and shaped during the winding process. This enables the winding of complex shapes and tight configurations, ensuring optimal space utilization within the transformer.

Corrosion Resistance: Copper has good corrosion resistance, protecting the windings from the effects of moisture, oxidation, and environmental factors. This helps maintain the long-term reliability and performance of the transformer.

Low Impurity Content: High-quality copper foil strip for transformer winding is typically produced with low impurity levels, ensuring the purity and electrical conductivity of the material. This purity contributes to the overall efficiency and reliability of the transformer.

Compatibility with Insulating Materials: Copper foil strip is compatible with various insulating materials used in transformer windings, such as paper, polyester film, and other insulation systems. It allows for reliable and secure winding configurations with excellent electrical insulation properties.

These features collectively make copper foil strip a preferred choice for transformer winding applications. Its combination of electrical conductivity, mechanical strength, thermal properties, and compatibility with insulating materials contributes to the overall performance, efficiency, and longevity of transformers.

Looking For A Trust Copper Foil Strip For Transformer Winding Manufacturer?

Contact us today and we’ll put together a quote tailored to your needs.