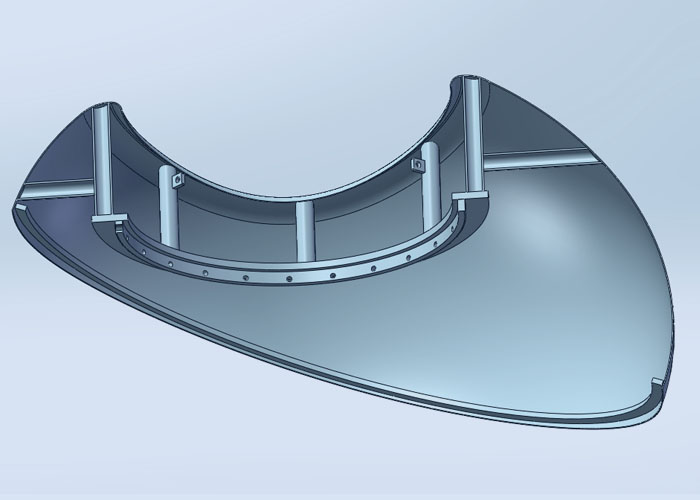

Custom Aluminum Alloy Parts

When it comes to custom aluminum alloy parts and fabrication, Seather offers completely ranges of customized aluminum fabrication solution from raw materials to quality customzied aluminum components.

Compared to stainless steel raw materials, aluminum alloy is a popular choice for fabrication because it has lightweight, corrosion resistant, good strength, non-sparking, and non-magnetic advantages. So the customized aluminum alloy parts are widely welcomed.

Aluminum alloy is a low-cost material for custom alloy parts and prototypes, whether it is mass production or rapid metal prototyping.

Your Trusted Custom Aluminum Alloy Parts Manufacturer In China

Aluminum alloy fabrication is one of our core capabilities.

Seather is committed to providing a full range of alloys and stainless steels fabrication services, starting from the customer’s needs: product design, mold design, mold fabrication, batch manufacturing, installation testing, and complete surface treatment and heat treatment.

Our factories and fabrication facilities are filled with highly skilled craftsmen, fitters, fabricators, welders with excellent safety and quality performance records.

We take great pride in not only meeting, but exceeding our customers’ expectations in all areas, including performance, design, logistics, schedule, delivery and cost.

| Service | Custom Aluminum Fabrication |

| Size | As Customers’ Request |

| Raw Material | Aluminum Alloy 6000 Series: 6061, 6063, 6082 AL7075, AL5052, AL3003 Aluminum: 1060, 1070, etc |

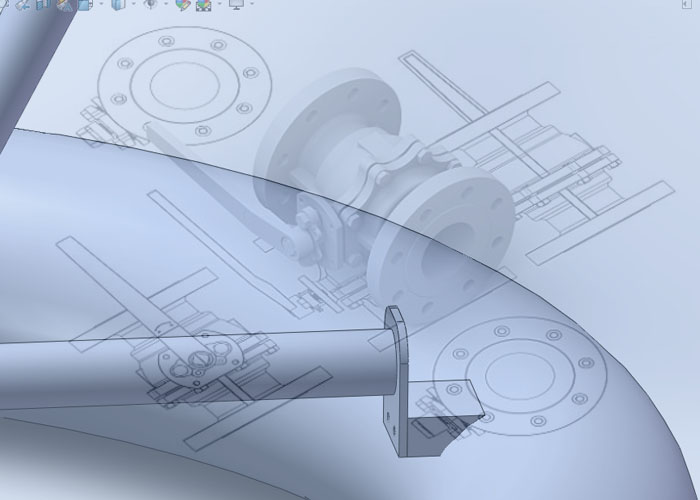

| Process Method | CNC Machining, Turning, Milling, Drilling, Grinding, Wire EDM Cutting, Sheet Metal, Welding, etc |

| Surface Treatment | Powder Coating, Brushing, Polishing, Sandblasting, Anodizing, Painting, Plating, Silk Printing, Dacromet, Passivation, Black Oxidation, etc |

| Tolerance | As Drawing Request |

| OEM/ODM Service | Available |

| Trial Sample Time | 5-7days |

| Design Format | PRO/E, Auto CAD, Solid Works, UG, CAD/CAM/CAE, etc |

| Trade Term | EXW, FCA, FOB, CNF, CIF, DDP |

| Payment Term | T/T, L/C, Western Union |

| QC Control | Full Support |

| Packing | PP bag/EPE foam/Carton boxes or wooden cases As customer’s specific requirements |

| Delivery | 7-30 days after receive the deposit payment |

| Shipment Term | 1) 0-100kg: (DHL/TNT/UPS/FEDEX International Express) / Air freight |

| 2) >100kg: Sea freight or as customized specification |

- All our aluminum parts are produced according to DIN / EN and ASTM standards.

- Non-standard size will be produced by customer drawings.

- Inner packaging: plastic wrap, bubble bag, PE foam, EPE cotton, PP bag etc;

- Outer packaging: carton box, wooden case, wooden pallets etc;

- Customized packaging as your request (Logo or other contents accepted to be printed on the custom parts outside packaging);

- Other special packaging will be designed as customer’s request;

- Shipping port: Shanghai, Ningbo or as your request.

Custom Aluminum Alloy Parts Materials & Grades

- 1xxx: 1050, 1050A, 1060, 1100

- 2xxx: 2014, 2017, 2024

- 3xxx: 3003, 3004, 3005, 3105

- 5xxx: 5005, 5052, 5754, 5083

- 6xxx: 6061, 6082, 6063

- 7xxx: 7075

For more aluminum raw materials information about custom parts, contact SEATHER expert team now!

Custom Aluminum Alloy Parts Fabrication Techniques

- Design & Modeling

- Source aluminum alloys materials

- CNC machining

- Sheet metal fabrication

- Welding

- Inspecting

- Surface treatment: Deburring, Polishing, sand blasting, etc.

- Assembly and test

- Inspection and packing

Why Choose SEATHER to Customize Your Aluminum Alloy Parts

At Seather, we are a one-stop-shop that that you can rely on for all of your custom aluminum fabrication demands.

Whether you have a concept of your own, or a design already in progress, our professional engineers team can help you make the idea into reality.

Seather owned advanced CNC processing production lines which can support you Aluminum CNC Machining Part with competitive price and good service.

We have powerful manufacturing capability, our automatic lathes, CNC lathes, CNC machining centers, stamping machines and cold heading equipments plus auxiliary equipment like milling machine, grinding machine, wire EDM and the cooperation of our partners, we are able to support every different aluminum parts regardless of the prototyping or mass production.

Manufacturing Services & Powerful Capabilities

Our cost effective production for custom aluminum parts include die casting, bending, machining, sheet metal fabrication, welding, assembly, test, and any other metal processing techniques.

Need An Expert To Manufacture Your Custom Aluminum Alloy Parts?

Custom Aluminum Alloy Parts: The Ultimate Guide

When you choose to buy custom made aluminum alloy parts, there have some important points we need to know before we get started.

What are Custom Aluminum Alloy Parts?

Custom aluminum alloy parts refer to components or products made from aluminum alloys that are specifically designed and manufactured to meet the unique requirements and specifications of a particular application or project.

These parts are typically produced through custom machining, fabrication, or casting processes.

Custom aluminum alloy parts can be created in various shapes, sizes, and configurations, depending on the specific needs of the customer.

They can range from simple to complex designs and can serve a wide range of industries, including automotive, aerospace, electronics, construction, HVDC and more.

Custom Aluminum Alloy Parts Applications

Custom aluminum alloy parts have a wide range of applications across various industries.

Some common applications of custom aluminum alloy parts include:

- Aerospace Industry: Custom aluminum alloy parts are extensively used in the aerospace industry. They can be found in aircraft structures, engine components, landing gear, wing assemblies, and other critical aerospace applications. Aluminum alloys offer a combination of strength, lightweight properties, and corrosion resistance, making them ideal for aerospace applications where weight reduction and durability are essential.

- Automotive Industry: The automotive industry utilizes custom aluminum alloy parts in various applications. These include engine components, such as cylinder heads, engine blocks, and pistons, as well as suspension systems, wheels, body panels, and heat exchangers. Aluminum alloys provide lightweight solutions, improving fuel efficiency and enhancing vehicle performance.

- Electronics and Electrical Industry: Custom aluminum alloy parts are used in the electronics and electrical industry for heat sinks, chassis, enclosures, connectors, and electrical connectors. Aluminum alloys offer excellent thermal conductivity, allowing efficient heat dissipation and thermal management in electronic devices and systems.

- Construction and Architecture: Custom aluminum alloy parts are utilized in construction and architecture for applications such as curtain walls, window frames, door frames, roofing, and structural components. Aluminum alloys provide strength, corrosion resistance, and design flexibility, making them suitable for modern architectural designs and building structures.

- Marine Industry: Custom aluminum alloy parts find applications in the marine industry for boat building, ship structures, and marine equipment. Aluminum alloys offer good corrosion resistance in saltwater environments, making them suitable for marine applications where durability and weight reduction are crucial.

- Renewable Energy Sector: Custom aluminum alloy parts are used in the renewable energy sector, particularly in solar panel mounting systems, wind turbine components, and electrical distribution systems. Aluminum alloys provide lightweight and corrosion-resistant solutions, contributing to the efficiency and durability of renewable energy systems.

- Industrial Machinery and Equipment: Custom aluminum alloy parts are utilized in various industrial machinery and equipment, including conveyor systems, automation equipment, machine frames, and tooling. Aluminum alloys offer high strength, rigidity, and dimensional stability, making them suitable for demanding industrial applications.

These are just a few examples of the wide range of applications for custom aluminum alloy parts.

The versatility, strength, lightweight properties, and corrosion resistance of aluminum alloys make them a preferred choice in numerous industries and applications where customized solutions are required.

Features of Custom Aluminum Alloy Parts

- Light Weight

- High Strength

- Easy Machining

- Custom Surface Treatment

- Thermal And Electrical Conductivity

- Reflection Performance

- Non-Magnetic

- Low Temperature Resistance

What Are Custom Aluminum Alloy Parts Surface Treatment?

Surface treatment is one of the major part in whole production.

Different surface finish will be used for different custom aluminum parts.

Some common surface treatments for aluminium alloy parts include:

Anodizing: Anodizing is a popular surface treatment for aluminium alloys. It involves creating an oxide layer on the surface of the aluminium through an electrochemical process. Anodizing can provide corrosion resistance, improve wear resistance, and allow for coloring options.

Powder Coating: Powder coating is a technique where a dry powder is electrostatically applied to the surface of the aluminium alloys. The powder is then cured under heat, creating a durable and attractive finish. Powder coating offers a wide range of color options and provides excellent protection against corrosion, UV rays, and chemical exposure.

Painting: Painting is another surface treatment option for aluminium alloy parts. It involves applying a liquid paint coating to the surface, providing both aesthetic appeal and protection against environmental elements. Painting can be done in various colors and finishes to suit different design requirements.

Polishing: Polishing is a mechanical process that involves smoothing and shining the surface of the aluminium alloy parts. It can enhance the appearance and reflectivity of the metal, giving it a bright and reflective finish.

Brushing: Brushing is a surface treatment technique that creates a brushed or satin finish on the aluminium alloy parts. It involves using abrasive brushes or pads to create a pattern of fine parallel lines on the surface. Brushing can provide a unique aesthetic appeal and help hide minor surface imperfections.

Sandblasting: Sandblasting involves using abrasive materials, such as sand or grit, to blast the surface of the aluminium alloys. This process helps remove any impurities, oxides, or surface irregularities, resulting in a clean and textured surface finish.

Clear Coating: Clear coating is a transparent protective layer applied to the surface of aluminium alloy parts. It helps preserve the natural appearance of the metal while providing resistance against oxidation, staining, and environmental damage.

Conclusion

Unquestionably, it is quite apparent that custom aluminum part revolves around numerous aspects, some of which we haven’t looked into here. But for now, at least you have the idea of what it takes to buy and install a functional aluminum parts that yields efficiency.

We are hopeful that this guide has been significantly helpful to you in many ways. And for that reason, it would be prudent if you also feel free to share it on your social media handles.

You know what, someone might also be looking for this kind of valuable information and you may be of considerable help too.

Otherwise, if you have any questions, recommendations, or concerns, you may also feel free to contact our Seather expert team. For sure, we will gladly offer the necessary assistance.

Looking For A Trust Custom Aluminum Alloy Parts Manufacturer?

Contact us today and we’ll put together a quote tailored to your needs.