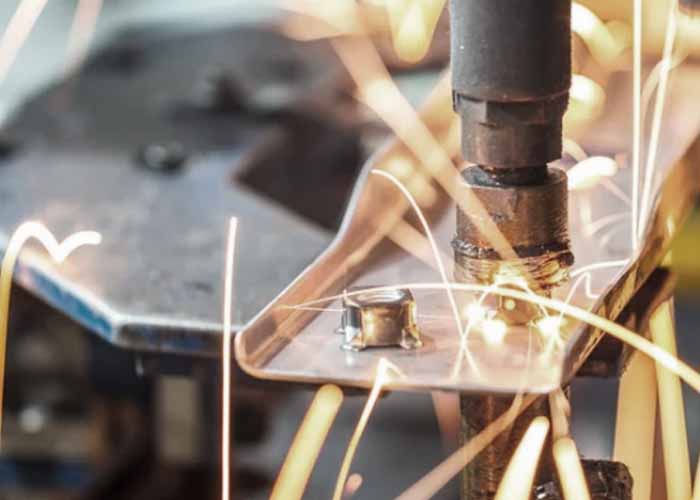

Metal Welding Service

Seather provides some of the best solutions ranging from custom metal welding and related services.

- Materials Available (nickel alloys & stainless steels)

- MIG Welding (metal inert gas)

- TIG Welding (tungsten inert gas)

- Metal Spot Welding

TRUSTED BY OVER 1K+ GLOBAL COMPANIES

Why Choose SEATHER as Your Expert Welder

Metal welding is used in a variety of industries, from heavy construction to manufacturing to automotive. It is an essential process for many projects, both large and small. Whether you’re building a house or manufacturing a tank, welding process is likely involved.

We have experience welding a diverse array of raw materials including Stainless Steel, Nickel alloys, Titanium and Aluminum alloys.

We specialize in advanced TIG welding of stainless steel and nickel alloys with additional strengths in MIG welding, copper brazing, and soldering.

Our welders are expert fabricators capable of delivering jewelry store quality weldments.

Our Welding Processes

Depending on the requirement, different welding techniques are used in sheet metal fabrication. Our highly skilled welders are able to carry out the following welding processes:

TIG Welding

Gas Tungsten Arc Welding (GTAW), also known as TIG Welding, is a joining process used on stainless steel. An arc welding process, TIG welding involves the use of an non-consumable tungsten electrode in order to deliver a weld.

MIG Welding

Metal Inert Gas (MIG) welding is an arc welding process that uses a continuous solid wire electrode heated and fed into the weld pool from a welding gun.

Spot Welding

Spot welding (also known as resistance spot welding) is a resistance welding process. This welding process is used primarily for welding two or more metal parts.

The Benefits Of Metal Welding Services

The Top 4 Reasons:

Functionality

Welding can be applied to stainless steel and nickel alloy products and projects to maximize the functionality of the end product.

Cost-effectiveness

One of the most economical ways to combine two metal parts, and is highly efficient, which greatly saves manufacturing costs.

Permanence

Metal welding is a permanent assembly in which materials are melted and joined together, which is similar to a whole material.

Stronger Joints

Welded joints are often stronger than those made with other methods, making them ideal for critical applications.

Metal Welding Materials

Stainless steel and nickel alloy are popular in metal welding and machining services for its excellent mechanical properties.

Nickel Alloys Materials

Nickel based alloys are also referred to as ni-based superalloys due to their outstanding strength, heat resistance and corrosion resistance.

Nickel and nickel based alloys are used for a wide variety of applications, the majority of which involve corrosion resistance and heat resistance.

Stainless Steels Materials

Stainless steel, any one of a family of alloy steels usually containing 10 to 30 percent chromium.

It has the characteristics of good processing performance and high toughness, and is widely used in industries.

Get Your Custom Metal Welding Parts Done

in 4 Simple Steps

Upload Design Files

STL , STEP (.stp), IGES (.igs), (.ZIP), or PDF. Also be a sample or an idea

01

Quote & Design Analysis

Seather expert team will analyze your design and send you pricing

02

Manufacturing Begins

We will begin the manufacturing process after you accept our quote. We also offer finishing options

03

On-Time Delivery

Keeping delivery promises, approved by 1800+ global industries end users.

04

Ready to Get Started?

Contact us today and we’ll put together a quote tailored to your needs.