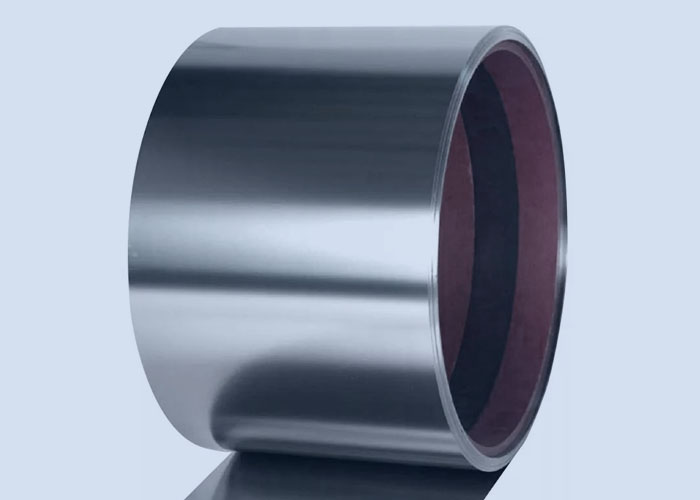

Stainless Steel Strips

As a leading China stainless steel strips supplier, SEATHER manufactures and produces different sizes and grades of stainless steel strips.

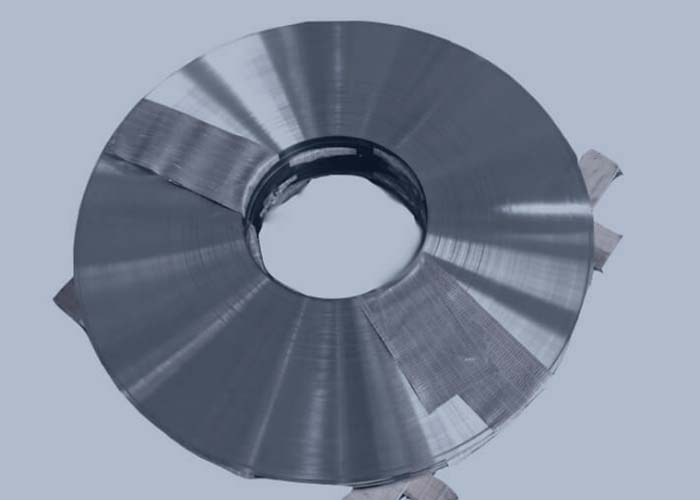

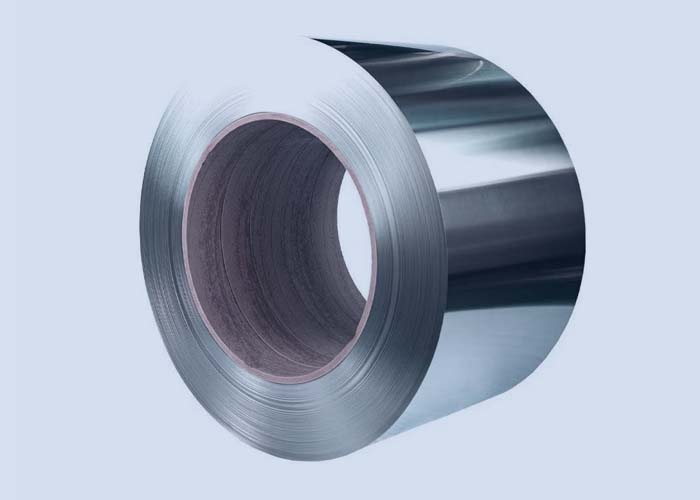

The stainless steel strips are the extension products of ultra-thin stainless steel coils, usually long and narrow stainless steel strips are manufactured to meet the demands of various industrial and mechanical areas.

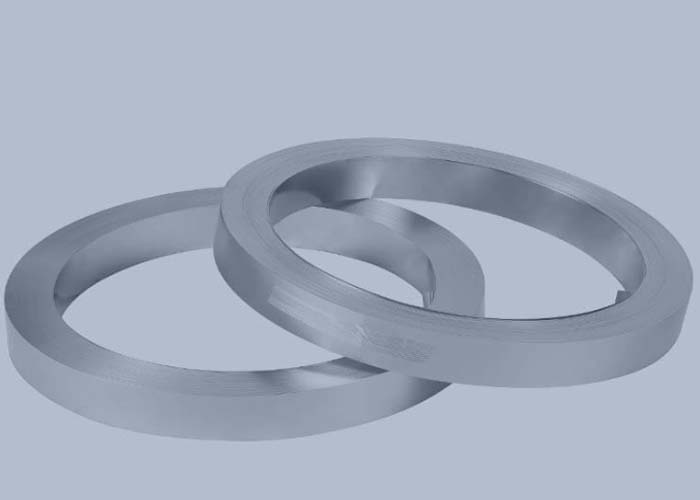

The stainless steel strips is also called narrow stainless steel tapes. The maximum width of its size shall not exceed 650mm, but the length of each coil is not limited.

Whatever size at whatever tight tolerance of nickel based alloys foils you demand, SEATHER here is sure to have it!

| Product Name | Stainless Steel Strips |

| Grades | Austenite steel 301, 304, 321, 316Ti, 316L, 304L, 304, 309S, 310S, 347, 317L, duplex and super stainless steel 2205, 2507, F53, 2101, 2304, 904L, 926, etc. |

| Standards | ASTM, ASME, DIN, JIS, GB/T, etc. |

| Thickness | 0.1mm-3.0mm |

| Width | 5mm-650mm |

| Edge | Slit/Round/Deburred |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø 150mm, Ø300mm, Ø400mm, Ø500mm paper core, special internal diameter core and without paper core on special request |

| Surface Finish | Mill/Bright/TR/Polishing/Annealing |

| Applications | Stainless steel strips are ideally suited for a wide range of industries that require high-performance materials, including aerospace, marine, chemical processing, nuclear power generation and oil&gas production |

| Packaging | Wooden pallet/Wooden case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 7-10 working days |

| MOQ | 500 Kgs |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of stainless steel strip is available |

| Remark | Stainless steel strips can be customized |

- Standard Export Packaging;

- Waterproof Paper Winding+PVC Film+Strap Banding+Wooden Pallet or Wooden Case;

- Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

- Other special packaging will be designed as customer’s request;

- Eye to wall and eye to sky are both available;

- Shipping port: Shanghai, Ningbo or as your request.

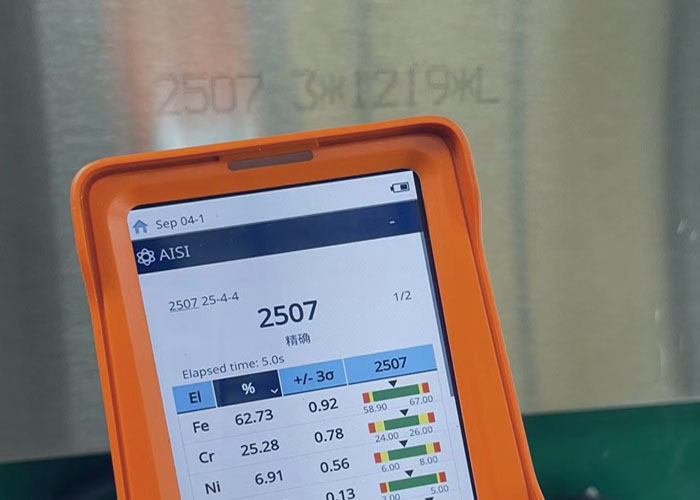

Stainless Steel Strips Materials & Grades

High quality custom stainless steel strips are made from below prime stainless steel coils materials, such as:

Austenite steel 301, 321, 316Ti, 316L, 304L, 304, 309S, 310S, 347, 317L, Precipitation Hardening 17-4 PH, 17-7 PH, Duplex and super duplex stainless steel 2205, 2507, F53, 2101, 2304, Special stainless steel 904L, S31254, 1.4529, 926, 20, A286, etc.

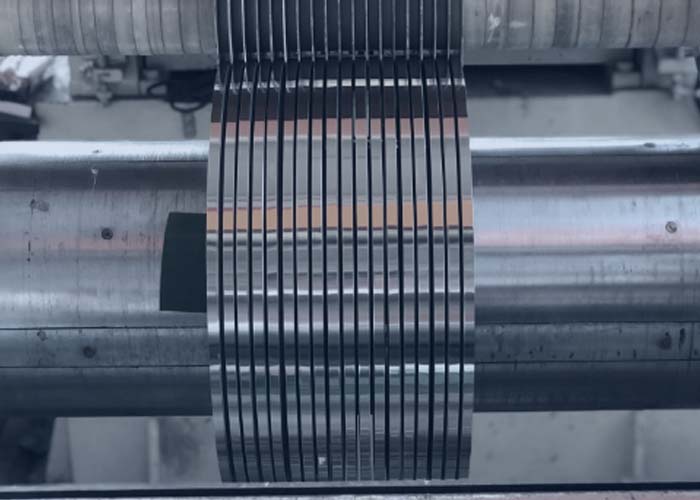

Stainless Steel Strips Production Process?

- Technical Analysis

- Raw Material Preparation

- Rolling And Bright Annealing Process

- Degrease Cleaning Process

- Tension Straightening Process

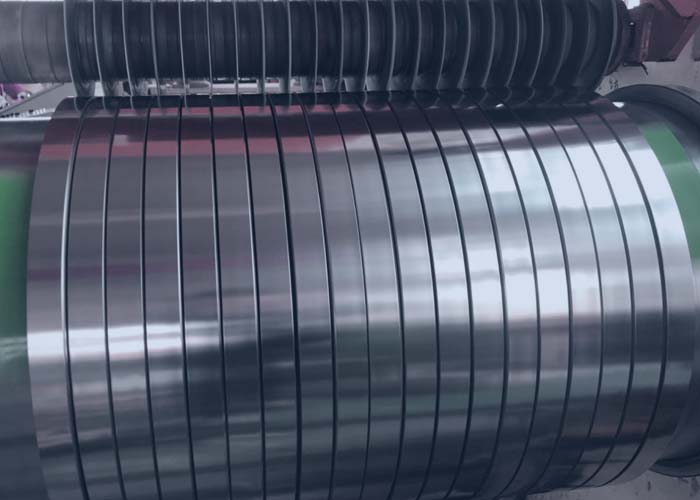

- Slitting Process

- Inspection Process

- Packaging Process

Your Reliable Stainless Steel Strips Manufacturer In China

Stainless Steel Strips: The Ultimate Guide

When you choose to buy precision stainless steel strips, there have some important points we need to know before we get started.

What are Stainless Steel Strips?

Stainless steel strip coil is rolled by cold rolling mill at room temperature.

The conventional thickness is between 0.1mm and 3mm, and the width is between 5.0mm and 650mm.

Cold rolled stainless steel strip has many advantages such as smooth and flat surface, high accuracy, good mechanical properties, and can be rolled or processed into coated steel plates.

The sequence of the production process is pickling, normal temperature rolling, process lubrication, annealing, leveling, precision cutting, and packaging.

Stainless Steel Strips Applications

Generally speaking, the application industry can be divided into the following two categories:

- Precision stainless steel strips products for high-end industries: aerospace industry; petrochemical industry; precision electronics industry; medical equipment; precision instrument.

- Precision stainless steel strips products for mid-range industries: electronic information industry; household appliances industry; kitchen and tableware; building decoration industry; hardware industry.

What are Stainless Steel Strips Surface Finish?

Through different processing methods of cold rolling and surface reprocessing after cold rolling, the surface finish of stainless steel can have different types.

The surface processing of stainless steel strips have NO.1, 2B, No. 4, HL, No. 6, No. 8, BA, TR hard, Rerolled bright 2H, polishing bright and other surface finishes, etc.

- NO.1: No. 1 surface refers to the surface obtained by heat treatment and pickling after hot rolling of the stainless steel strip. It is to remove the black oxide scale produced during hot rolling and heat treatment by pickling or similar treatment methods. This is No. 1 surface processing. The No.1 surface is silvery white and matt. Mainly used in heat-resistant and corrosion-resistant industries that do not require surface gloss, such as alcohol industry, chemical industry and large containers.

- 2B: The surface of 2B is different from the 2D surface in that it is smoothed with a smooth roller, so it is brighter than the 2D surface. The surface roughness Ra value measured by the instrument is 0.1~0.5μm, which is the most common processing type. This kind of stainless steel strip surface is the most versatile, suitable for general purposes, which is widely used in the chemical, paper, petroleum, medical and other industries, and can also be used as a building curtain wall.

- TR Hard Finish: TR stainless steel is also called hard steel. Its representative steel grades are 304 and 301, they are used for products that require high strength and hardness, such as railway vehicles, conveyor belts, springs and gaskets. The principle is to use the work hardening characteristics of austenitic stainless steel to increase the strength and hardness of the steel plate by cold working methods such as rolling. The hard material uses a few percent to several tens of percent of the mild rolling to replace the mild flatness of the 2B base surface, and no annealing is carried out after rolling. Therefore, the TR hard surface of the hard material is the rolled after cold rolling surface.

- Rerolled Bright 2H: After the rolling process. the stainless steel strips will be processed bright annealing. The strip can be fast cooled by the the continuous annealing line. The traveling speed of the stainless steel strip on the line is around 60m~80m/min. After this step, the surface finish will be 2H rerolled bright.

- No.4: The surface of No. 4 is a fine polished surface finish that is brighter than the surface of No. 3. It is also obtained by polishing the stainless steel cold-rolled stainless steel plate with 2 D or 2 B surface as the base and polishing with abrasive belt with a grain size of 150-180# Machined surface. The surface roughness Ra value measured by the instrument is 0.2~1.5μm. NO.4 surface is widely used in restaurant and kitchen equipment, medical equipment, architectural decoration, containers, etc.

- HL: HL surface is commonly called hairline finish. Japanese JIS standard stipulates that 150-240# abrasive belt is used to polish the continuous hairline-like abrasive surface obtained. In China’s GB3280 standard, the regulations are rather vague. HL surface finish is mostly used for building decoration such as elevators, escalators, and facades.

- No.6: The surface of No. 6 is based on the surface of No. 4 and is further polished with a Tampico brush or abrasive material with a particle size of W63 specified by GB2477 standard. This surface has a good metallic luster and soft performance. The reflection is weak and does not reflect the image. Due to this good property, it is very suitable for making building curtain walls and building fringe decorations, and also widely used as kitchen utensils.

- BA: BA is the surface obtained by bright heat treatment after cold rolling. Bright heat treatment is annealing under a protective atmosphere that guarantees that the surface is not oxidized to preserve the gloss of the cold-rolled surface, and then use a high-precision smoothing roll for light leveling to improve the surface brightness. This surface is close to a mirror finish, and the surface roughness Ra value measured by the instrument is 0.05-0.1μm. BA surface has a wide range of uses and can be used as kitchen utensils, household appliances, medical equipment, auto parts and decorations.

- No.8: No.8 is a mirror-finished surface with the highest reflectivity without abrasive grains. The stainless steel deep processing industry also calls as 8K plates. Generally, BA materials are used as raw materials for mirror finishing only through grinding and polishing. After mirror finishing, the surface is artistic, so it is mostly used in building entrance decoration and interior decoration.

Looking For A Trust Stainless Steel Strips Manufacturer?

Contact us today and we’ll put together a quote tailored to your needs.