Metal Forging Service

Seather provides metal forging and machining service with cold forging, hot forging, rounded or rectangular in shape.

- Materials Available (nickel alloys & stainless steels)

- MIG Welding (metal inert gas)

- TIG Welding (tungsten inert gas)

- Metal Spot Welding

TRUSTED BY OVER 1K+ GLOBAL COMPANIES

Why Choose Our Forging Services

Metal welding is used in a variety of industries, from heavy construction to manufacturing to automotive. It is an essential process for many projects, both large and small. Whether you’re building a house or manufacturing a tank, welding process is likely involved.

We have experience welding a diverse array of raw materials including Stainless Steel, Nickel alloys, Titanium and Aluminum alloys.

We specialize in advanced TIG welding of stainless steel and nickel alloys with additional strengths in MIG welding, copper brazing, and soldering.

Our welders are expert fabricators capable of delivering jewelry store quality weldments.

Our Metal Forging Processes

Depending on the requirement, different welding techniques are used in sheet metal fabrication. Our highly skilled workers are able to carry out the following metal forgings processes:

Cold Forging

It refers to metal forging at room temperature, compared to hot forging, cold forging take advantage of dimensional control, product uniformity, surface finish, and contamination. Cold forging involves different techniques such as bending, extruding, cold drawing, and cold heading. Cold forging is more suitable for handling softer materials, higher productivity and interchangeability can be offered. Cold forging also brings more precise tolerances than hot or warm forging.

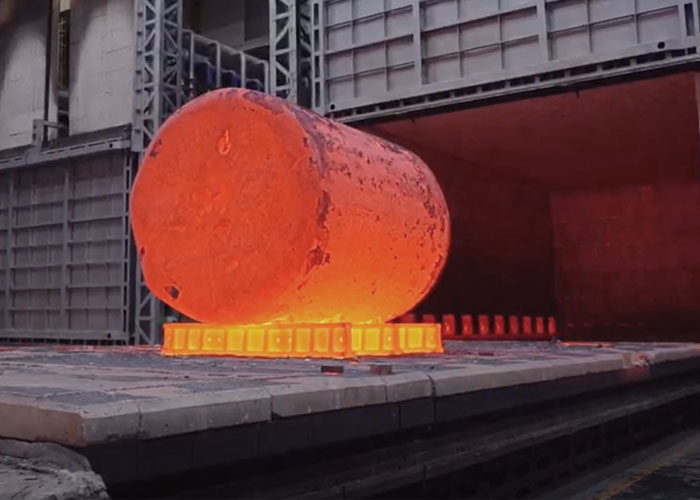

Hot Forging

It needs to heat the metal above the recrystallization temperature, due to high temperature decreases the yield strength increases ductility, hot forging can reduce the required energy to form the metal and avoid hardening, also eliminate the chemical inconsistencies. Most metals are processed with hot forging, metal is more pliable with extreme heat.

Closed Die Forging

It also known as impression die forging, in the process, the metal is put in a die, the hammer is dropped on the workpiece, leading to the metal flow and fill the die cavities, excess metal is squeezed out of the die and them forming flash, the flash cools faster than the rest of the material and helps prevent more flash generated, this also forces the metal fill the cavity completely. When the forging process is finished, the flash will be removed.

Open Die Forging

It also known as smith forging, involves the use of two dies usually flat in shape, the dies do not enclose the workpiece, which allows it to flow everywhere except where it contacts the dies, the operator needs to orient and position the part to get the desired shape. The main benefits of open die forging are continuous grain flow, reduced voids, increased strength and fatigue resistance, improved microstructure, finer grain size, and better internal quality. Open-die forgings can be worked into discs, hubs, blocks, shafts, sleeves, cylinders, flats, plates, and some custom shapes.

The Benefits Of Metal Forging Services

The Top 4 Reasons:

Leak-resistance

Metal forged components are created from extremely dense, non-porous metals. The durability of metal allows you to design a part with thin units or pieces without risking future defects or leaks.

Lower Costs

Making more parts at one time will result in lower prices while still keeping the quality high.

Corrosion Resistance

Many forgings we produce require unique surface coatings that protect from future rust corrosion.

Tight Tolerances

Part dimensions are more exact than in casting methods. If you need to have multiple forgings produced, tight tolerances allow for minimum variation between components.

Metal Forging Materials

Raw Materials: stainless steel and nickel based alloys

Nickel Alloys Forging

Nickel alloys forging is widely used in the industry, include forging shaft, forging rings and so on with many advantages.

Stainless Steels Forging

Stainless steel forging is widely used in the industry, include forging shaft, forging rings, etc. The main advantage of stainless steel is corrosion resistance or high-temperature resistance.

Get Your Custom Metal Forgings Done

in 4 Simple Steps

Upload Design Files

STL , STEP (.stp), IGES (.igs), (.ZIP), or PDF. Also be a sample or an idea

01

Quote & Design Analysis

Seather expert team will analyze your design and send you pricing

02

Manufacturing Begins

We will begin the manufacturing process after you accept our quote. We also offer finishing options

03

On-Time Delivery

Keeping delivery promises, approved by 1800+ global industries end users.

04

Metal Forging Service Applications

Forging has been used for a long history and still offers cost-effective solutions for various industries across the globe. It facilitates the high volume production of forging components with excellent mechanical properties. Our forging services can assist you in cost savings and reputation improvements.

- Defense

- Automotive

- Mining

- Oil & Gas

- Surgical & Dental

- Energy

- Agriculture

- Transportation

- Railroad

- Construction

Ready to Get Started?

Contact us today and we’ll put together a quote tailored to your needs.