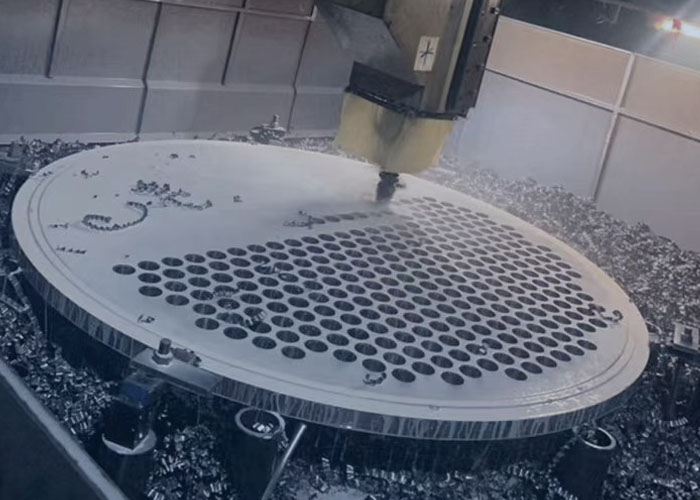

Tube Sheet Drilling Service

SEATHER provides machining and drilling service for almost all tube sheets, small or large in size, rounded or rectangular in shape

- Materials Available (nickel alloys & stainless steels)

- Tube sheets with outer diameter more than 10000mm

- Tube sheets holes deep thickness up to 1100mm

- Tube sheets holes diameter range from 12mm to 54mm

- The hole side deviation per meter is within 0.3mm

TRUSTED BY OVER 1K+ GLOBAL COMPANIES

Why Choose SEATHER’s Tube Sheet Drilling Service

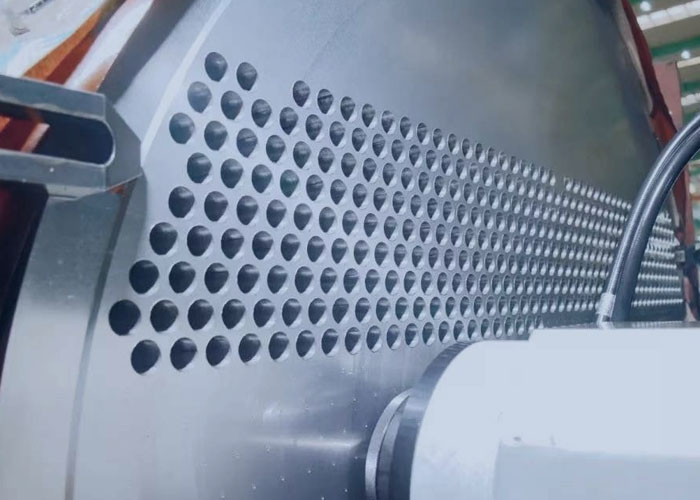

A tube sheet (or tube plate), is a flat plate with a number of small holes evenly distributed which are used to fix and support thin walled tubes in parallel.

We have contracted to custom make a variety of tube sheets and baffle plates for heat exchangers, boilers, containers used in many industries like vaccine equipment, paper making, petro-chemical, water-treatment, new energy, etc. The bespoke tube sheets and baffle plates we have produced feature as below:

- Immense size with diameter up to 10000mm (10 meters)

- High precision, very narrow tolerance, fix the tubes tightly

- Deep boring possible up to 1100mm

- Complex hole shapes possible

- Multi machining processes adopted for different designs

- A variety of materials available, including stainless steel and nickel alloy, etc.

Our cost effective precision metal machining for tube sheets and baffle plates include planing, cutting, milling, drilling, grinding, and any other metal processing techniques.

Usually, for a round tube sheet or baffle not very thick, we can get the workpiece from cutting the metal sheet. Equipped with all series of world-class CNC machine tools, SEATHER have the ability to complete a variety of tube sheets with tight tolerances in a few days after receiving the orders.

Our Tube Sheet Drilling Service Processes

Depending on the customer requirement, advanced manufacturing techniques are used in tube sheet fabrication. Our highly skilled fabricators are able to carry out the following production processes:

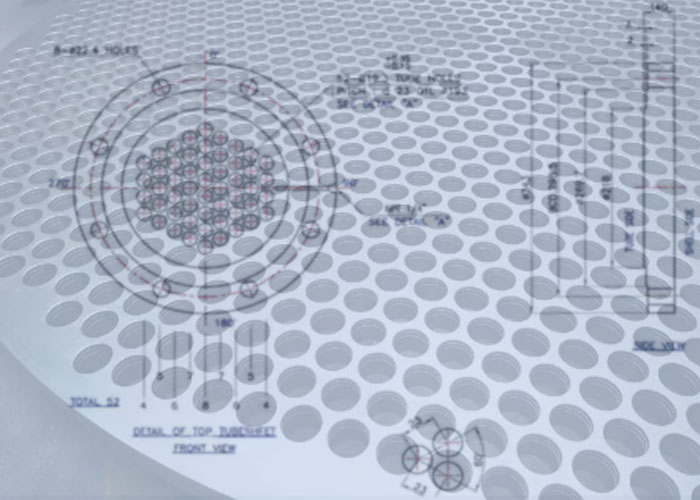

Tube Sheet Drawing Design

Tube Sheet Drilling & Machining

Tube Sheet Inspection

The Benefits Of Tube Sheet Drilling Service

The Top 3 Reasons:

Functionality

Cost-effectiveness

Permanence

Tube Sheet Drilling Service Materials

Stainless steel and nickel alloy are popular in tube sheet drilling and machining services for its excellent mechanical properties.

Nickel Alloys Materials

Nickel based alloys are also referred to as ni-based superalloys due to their outstanding strength, heat resistance and corrosion resistance.

Nickel and nickel based alloys are used for a wide variety of applications, the majority of which involve corrosion resistance and heat resistance.

Stainless Steels Materials

Stainless steel, any one of a family of alloy steels usually containing 10 to 30 percent chromium.

It has the characteristics of good processing performance and high toughness, and is widely used in industries.

Get Your Custom Tube Sheet Done

in 4 Simple Steps

Upload Design Files

STL , STEP (.stp), IGES (.igs), (.ZIP), or PDF. Also be a sample or an idea

01

Quote & Design Analysis

Seather expert team will analyze your design and send you pricing

02

Manufacturing Begins

We will begin the manufacturing process after you accept our quote. We also offer finishing options

03

On-Time Delivery

Keeping delivery promises, approved by 1800+ global industries end users.

04

Drilling Custom Tube Sheet Applications

Tube plate sheet is widely used in tubular heat exchangers, boilers, pressure vessels, steam turbines, large central air conditioners, condensers, evaporators and other products.

The stainless steel and nickel alloy material makes it not only rigid, but also has great heat conduction performance.

The precision of tube plate processing, especially the tolerance of hole spacing and diameter, perpendicularity, and finish greatly affect the assembly and performance of the equipment listed above.

Ready to Get Started?

Contact us today and we’ll put together a quote tailored to your needs.