CNC Machining Services

Custom CNC machining parts in nickel alloy and stainless steel delivery in as fast as 3 days

- 100K+ Mass Production Machining

- Tolerance as tight as ±0.01 mm

- Advanced 4-axis and 5-axis CNC machining equipment

TRUSTED BY OVER 1K+ GLOBAL COMPANIES

CNC Machining Processes

CNC Milling

CNC milling is a subtractive process that using 4-axis and 5-axis milling machines with various of cutting tools to remove materials from nickel alloys and stainless steel blocks into final parts with different geometries as designed.

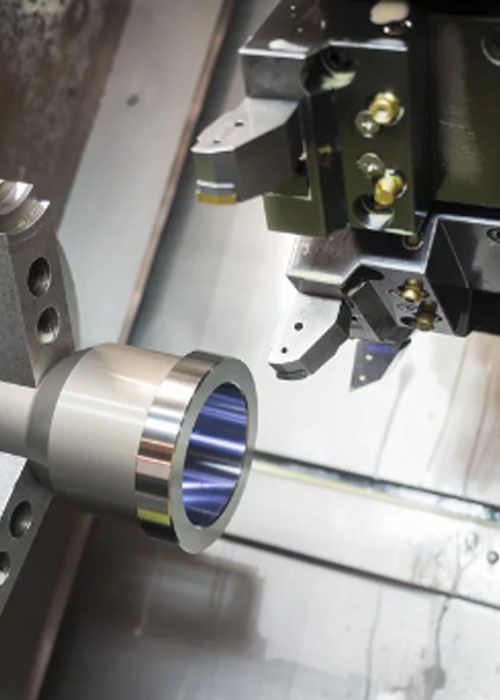

CNC Turning

CNC turning is a more efficient method to manufacture round shaped components from stainless steel and nickel alloy round bars or pipes, such as shafts, worms. Combines with live tooling, milled geometries can be done in the meantime.

Why Choose Us for Custom CNC Machining?

The Top 3 Reasons:

Industry Experience

Our engineers team have built up rich and deep experience from many cooperated projects, so they can handle complex and precision parts in several industries without any problem.

Advanced Equipment

We use advanced 4-axis and 5-axis CNC machining equipment to create complex surface and multi-curved metal parts processing. Materials including stainless steels & nickel alloys can be easily processed at one time.

Fast Delivery Time

On average we return quotes within 24 hours, metal cnc machining parts ship within 5 days or less, and we have a 99+% on-time delivery and quality rate. 24/7 service, also easily face to face meeting, fast feedback.

CNC Machining Materials & Finishes

If you are considering manufacturing your parts with CNC machining, it is important to know what kind of metal materials and finishes can be applied to your CNC machined parts.

SEATHER uses high quality metal materials for our CNC machining process. Among our materials are stainless steel, nickel alloys, titanium and more. Each material is available in different grades and varieties. If you want a specific material or special surface finish to be used in the CNC machining part, don’t hesitate to contact our expert team!

CNC Machining Nickel Alloys Materials

Nickel based alloys are also referred to as ni-based superalloys due to their outstanding strength, heat resistance and corrosion resistance.

Nickel and nickel based alloys are used for a wide variety of applications, the majority of which involve corrosion resistance and heat resistance.

CNC Machining Stainless Steels Materials

Stainless steel, any one of a family of alloy steels usually containing 10 to 30 percent chromium.

It has the characteristics of good processing performance and high toughness, and is widely used in industries.

CNC Machining Finishes

Machined Finish: The most popular and cost efficient way for inner functional components. Fine and even tool path is also good for aspect parts.

Bead Blasted: The part is left with a matt appearance. Range of 120 to 320 beads allows us to create different roughness to the surface.

Anodized: The metal or alloy product is used as an anode, and an oxide film is formed on the surface by electrolysis. Metal oxide films change the surface state and properties, such as surface coloration, improve corrosion resistance, enhance wear resistance and hardness, which protects parts surfaces. This method is widely used in custom cnc machined fasteners, mechanical parts, aircraft and auto parts, precision instruments and radio equipment, daily necessities and architectural decoration.

Powder Coating: Powder coating is the use of powder spraying equipment to spray powder coating on the surface of the workpiece.

The spraying effect of powder spraying is superior to the normal spraying process in terms of mechanical strength, adhesion, corrosion resistance and aging resistance, and the cost is low.

CNC Machining Tolerances

With a wide range of CNC machines, we are able to provide stand tolerance CNC machined alloys parts with the most economic price and super precision tolerance.

When working with SEATHER, our team guarantee all custom parts will be made accordingly to your specification.

If 2D model drawings are not available, you can also indicate with ISO 2678 as well. Learn more about the ISO 2678 tolerance standard.

| Dimension | Production Tolerances |

| 0.5 – 6.00 mm | ± 0.05 mm |

| 6.00 – 30.00 mm | ± 0.10 mm |

| 30.00 – 120.00 mm | ± 0.15 mm |

| 120.00 – 400.00 mm | ± 0.20 mm |

| 400.00 – 1000.00 mm | ± 0.30 mm |

| Angular: ±0.5° | |

| Surface Roughness 3.2μm Ra | |

Get Your CNC Machining Parts Done

in 4 Simple Steps

Upload Design Files

STL , STEP (.stp), IGES (.igs), (.ZIP), or PDF. Also be a sample or an idea

01

Quote & Design Analysis

Seather expert team will analyze your design and send you pricing

02

Manufacturing Begins

We will begin the manufacturing process after you accept our quote. We also offer finishing options

03

On-Time Delivery

Keeping delivery promises, approved by 1800+ global industries end users.

04

Applications of CNC Machining

Aerospace Industry

As one of the leading CNC machining aerospace parts manufacturers in China, Seather produces high-quality aerospace components and prototypes with tight tolerance and highest precision. With our advanced equipment and quality control, you will be sure of getting the aircraft components that meet your specific requirements and stringent needs of the aerospace industry.

CNC Machining Service FAQS

CNC machining is a manufacturing technique for removing material.

It uses sharp cutting tools, available in a variety of shapes and sizes, which are precisely controlled by a computer.

CNC stands for computer numerical control.

Looking For A Reliable China Precision CNC Machining Parts Manufacturer?

Contact us today and we’ll put together a quote tailored to your needs.