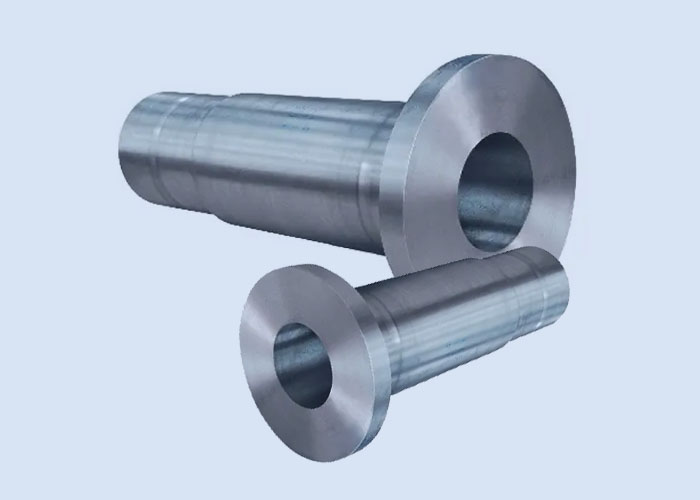

Custom Forgings

Custom forgings are created by compressing stainless steel and nickel alloy into specific shapes using high-pressure machinery equipment.

If you are seeking a manufacturer of forging services and custom forging products, here Seather is the good choice for you.

Welcome to send your inquiry or custom designs of forging parts to be made, we’ll send you a free quote within 24 hours in working days and work out a schedule for recording the progress.

Your Trusted Custom Forgings Manufacturer In China

Custom forging production fabrication is one of our core capabilities. Forging stainless steel and nickel based alloy piping systems, our projects consist of large capital projects with thousands of forgings, as well as routine maintenance and one flange forging orders.

Our factories and fabrication facilities are filled with highly skilled craftsmen, pipe fitters, pipe fabricators, pipe welders with excellent safety and quality performance records. We take great pride in not only meeting, but exceeding our customers’ expectations in all areas, including performance, design, logistics, schedule, delivery and cost.

| Product Name | Custom Forgings |

| Raw Materials | Different grade of titanium, nickel based alloy, duplex and super duplex stainless steel for custom pipe spool production, such as: Ti Gr1, Gr2, alloy 600, 625, 690, 800, 825, 800H, C-22, C-276, 400, Alloy 20, Duplex 2205, Super Duplex 2507, 904L, S31254, etc. |

| Size | Customized or according to your drawing |

| Samples | Sample available |

| Tolerance | +/-5mm to +/-0.1mm |

| Testing Equipment | CMM; Tool microscope; multi-joint arm; Automatic height gauge; Manual height gauge; Dial gauge; Marble platform; Roughness measurement |

| Logo | Custom logo available |

| Surface Treatment | Anodizing, Passivation, Polishing, Plating, Painting, Black Oxide, Powder Coating, Brushing, Heat Treatment, Surface Phosphating, Hot Dip Galvanizing, Surface Treatment Dacromet, etc |

| Color | Silver, black, gold, red, green, blue, purple, etc |

| File Formats | SolidWorks, Pro/E, AutoCAD (DXF, DWG), PDF, TIF, JPG, etc |

| Services | OEM/ODM, Engineering&Design Consulting, Assembly, Finishing, Materials Sourcing, Custom Packaging Services, etc |

| Quality System | ISO9001, SGS, TUV |

- All our pipe spools are produced according to DIN / EN and ASTM standards.

- Non-standard size will be produced by customer drawings.

- Inner packaging: plastic wrap, bubble bag, PE foam, EPE cotton, PP bag etc;

- Outer packaging: carton box, wooden case, wooden pallets etc;

- Customized packaging as your request (Logo or other contents accepted to be printed on the custom forgings outside packaging);

- Other special packaging will be designed as customer’s request;

- Shipping port: Shanghai, Ningbo or as your request.

Custom Forgings Materials & Grades

| MATERIALS | GRADES |

| Stainless Steels | Austenite steel 321, 316Ti, 316L, 304L, 304, 309S, 310S, 347, 317L, Precipitation Hardening 17-4, 17-7, Duplex and Super Duplex stainless steel 2205, 2507, F53, 2101, 2304, Special stainless steel 904L, S31254, 1.4529, etc. |

| Nickel Based Alloys | Alloy B, B-2, B-3, C-22, C-276, C-2000; Alloy 800, 800H. 800HT, 825, 925, A-286, 330; Alloy 600, 601, 625, 690, 718, X-750; Alloy 400, K-500; |

For more raw materials information about custom forgings, contact SEATHER expert team now!

Custom Forgings Fabrication Techniques

Forging Processes: cold forging, hot forging, roll forging, open-die forging, closed-die forging, drop forging, etc.

Raw Materials: stainless steel and nickel based alloys

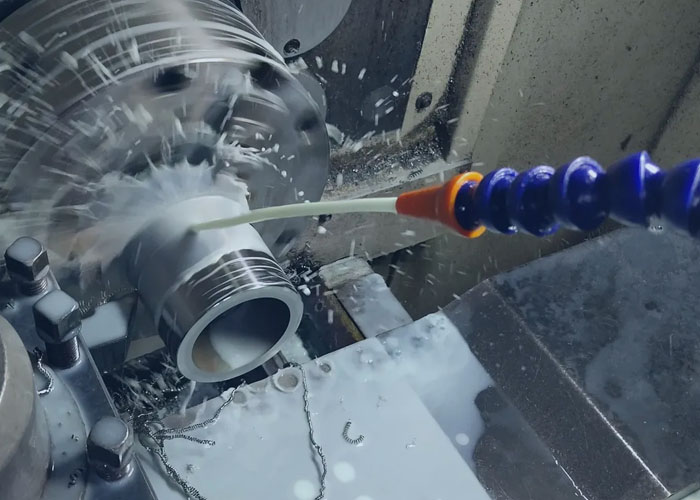

CNC Machining: turning, milling, drilling, grinding, tapping, boring, reaming, etc.

Surface Finishing: anodizing, plating, painting, polishing, powder coating, etc.

Quality Inspections: CMM, IPC, DPI, PM, PSI, etc.

Why Choose SEATHER to Customize Your Forgings

Custom Forgings Technology

Custom Forgings Machining

Custom Forgings Inspection

All the stainless steel and nickel alloy raw materials are purchased from domestic best material factory. We enjoy good pricing advantage for our large demands and long term coooperation. Prime quality material is the first important factor to produce quality forgings products.

Although sourcing forging parts from china companies directly can be risky and difficult to manage without experience, there are many variables. Sourcing through Seather will be able to reduce your cost of tooling up to 50% compared to the USA and EU manufactuers, and lower down the risk of other metal forging companies in China. Our in-house tooling and machining capabilities can also help our customers to save extra cost compared to outsourcing factories.

We have helped our clients to realise their innovation ideas with our rich experience in forging. Once the order is confirmed, we will provide a full solution to our customers for approval, and one off sample will be provided for free before mass production.

Manufacturing Services & Powerful Capabilities

Our cost effective precision metal machining and production forgings include planing, cutting, milling, drilling, grinding, and any other metal processing techniques.

Need An Expert To Manufacture Your Custom Forgings?

Custom Forgings: The Ultimate Guide

When you choose to buy custom forgings products from China, there have some important points we need to know before we get started.

What are Custom Forgings?

Forging is a typical manufacturing process of shaping metal using localized compressive forces, it is usually performed with forging tools like hammers or presses.

Main materials used for the forging process including nickel based alloys, stainless steel and titanium.

Forged materials can range in weight from less than a kilogram to hundreds of metric tons.

The common equipment and tools used for forging are hammer and anvil. The hammer is attached to an anvil, during the forging process, it is raised and dropped into the workpiece to add force.

The most common types of forging processes are cold forging and hot forging.

Custom Forgings Applications

Custom forging has been used for a long history and still offers cost-effective solutions for various industries across the globe.

It facilitates the high volume production of forging components with excellent mechanical properties.

Seather forging services can assist you in cost savings and reputation improvements.

- Oil & Gas

- Defense

- Automotive

- Mining

- Marine

- Surgical & Dental

- Power & Energy

- Agriculture

- Transportation

- Railroad

- Construction

Features of Custom Forgings

Leak-resistance: Metal forged components are created from extremely dense, non-porous metals. The durability of metal allows you to design a part with thin units or pieces without risking future defects or leaks.

Lower Costs: Making more parts at one time will result in lower prices while still keeping the quality high.

Corrosion Resistance: Many forgings we produce require unique surface coatings that protect from future rust corrosion.

Tight Tolerances: Part dimensions are more exact than in casting methods. If you need to have multiple forgings produced, tight tolerances allow for minimum variation between components.

What Are Custom Forgings Surface Treatment?

Surface treatment is one of the major part in whole production.

Different surface finish will be used for different custom forgings.

With methods including anodizing, passivation, brushing, polishing, blackened, plating, painting, powder coating, heat treatment, surface phosphating, hot dip galvanizing, surface treatment dacromet, etc.

Key Considerations When Buying Custom Forgings

When purchase the custom tube sheet from China manufacturer, you should know the standards, size, materials grades, production process, drawings details, etc.

Below Is One Sample Purchasing Tips For Your Reference

- Standards: ASTM A240

- Material Grade: 2205 duplex stainless steel

- Size: As your drawing request

- Usage: Oil & Gas

- Production Process: Cold forging, CNC machined

- Tolerance: -1mm/+1mm

- Requirement On Properties: As your request

- Order Quantity, Delivery Time, Shipping Method, Place Of Delivery, Packaging Requirement, etc. should be considered.

Conclusion

Unquestionably, it is quite apparent that custom forgings revolves around numerous aspects, some of which we haven’t looked into here. But for now, at least you have the idea of what it takes to buy and install a functional product that yields efficiency.

We are hopeful that this guide has been significantly helpful to you in many ways. And for that reason, it would be prudent if you also feel free to share it on your social media handles.

You know what, someone might also be looking for this kind of valuable information and you may be of considerable help too.

Otherwise, if you have any questions, recommendations, or concerns, you may also feel free to contact our expert team. For sure, we will gladly offer the necessary assistance.

More Resources

Custom Forgings FAQS

While the applications are similar, there are many differences between custom metal forgings and castings.

Custom metal forgings are generally superior to custom castings because of their durability and affordability. Other differences include:

- Component Strength: The high-pressure method used when producing forgings strengthens components in a way the casting process cannot. Metal forgings have far superior strength properties than castings, creating more durable parts.

- Cost: Parts produced through the casting process are more likely to contain defects. The high temperatures used in our forging techniques make more reliable parts and have far fewer deficiencies. Further, custom castings require extensive quality control and expensive inspection processes.

- Fewer defects: The casting method cannot always avoid the creation of metallurgical blemishes and surface flaws. The excellent quality of forgings ensures you will not have to replace or fix your parts year after year.

Looking For A Trust Custom Forgings Manufacturer?

Contact us today and we’ll put together a quote tailored to your needs.