Quality Control

Building a competitive advantage through quality management

Building a competitive advantage through quality management

SEATHER’s materials all from China and world top quality steel factories, with original MTC and all the certification file. The source is total transparent and tracable to customer, before shipment we invite third-party such as SGS, TUV or customer poiint inspection company to make the final test on quality follow standard requirement, to make sure our material all is quality guarranted to customer. SEATHER, your relaible supply chain of alloys and stainless steels always.

- Professional Specialist

- Brilliant Ideas

- Prime Quality

- 24/7 Assiatance

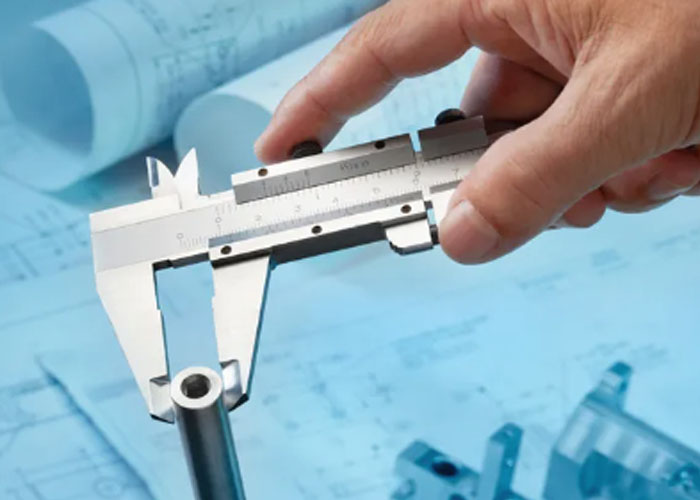

Quality Management

Every Seather alloy and stainless steel products comply with global standards through strict QC inspections, building a foundation for customer trust.

1.Raw Materials Checking

In order to ensure the quality of the production stainless steel and alloys materials, the incoming acceptance inspections are strictly and carefully inspected by specialized quality inspectors in accordance with the specified inspection content, inspection methods and inspection quantities.

2.Production Quality Checking

In the process of product quality monitoring in the production process, the quality of the produced products is effectively controlled, and inspections are carried out according to the procedures to prevent the outflow of unqualified products and ensure that the final products meet the qualified requirements.

3.Pre-Shipment Inspection

Before the product is shipped, in order to ensure that the shipped product meets the customer’s quality requirements, the product is inspected, and the product that has passed the inspection can be released for shipment. Inspection result records can be provided upon customer request.

More Alloys Resources

Aluminum Casting: A Guide for Beginners & Experts

Aluminum is a metal that is really abundant in today’s time and it is also one of the most useful and important metals for the

Aluminum Welding: A Guide for Beginners & Experts

The welding of the aluminum is an easy task for the beginners and experts. Beginners face some challenges because the welding of Aluminum requires specific

Stainless Steel vs. Aluminum Alloy: What’s the Difference?

Stainless steel and aluminum alloy are most widely used in industry and domestic purposes. Many things around you, from your house to your office, kitchenware

Stainless Steel vs. Nickel Based Alloy: A Comprehensive Comparison

Stainless steel is an iron-based alloy that contains chromium and nickel as the main alloy elements, along with other elements such as carbon, magnesium, sulfur,

Red Brass vs. Yellow Brass: What’s the Difference?

Brass is a unique alloy of copper and zinc. It is most commonly used in many applications due to its outstanding properties. Brass is categorized

6061 Aluminum vs. 6063 Aluminum: What’s the Difference?

Aluminum is a versatile material used very commonly these days due to its excellent properties and reasonable price. Aluminum alloys are divided into different grades

Consult Your Alloys & Stainless Steels Products Experts

Contact us today and we’ll put together a quote tailored to your needs.