CAD Design & 3D Modeling Services

Seather’s CAD design and 3D modeling services optimize every phase of the product development lifecycle through extensive design and engineering expertise.

- Professional engineer team support

- Powerful software design platform (UG, SW, AUTOCAD, PROE, etc.)

- 7/24 Service

- Rich engineering & management experience

TRUSTED BY OVER 1K+ GLOBAL COMPANIES

Why Choose SEATHER as Your Designer

Our highly experienced CAD designers and engineers utilize engineering oriented 3D Modeling software to create our customers’ new product designs.

This allows us to create easily modifiable, functional product designs, ready for prototyping and manufacturing. CAD software is just one of the many tools we use in our product development process to create new product ideas.

SEATHER’s CAD design and 3D modeling services optimize every phase of the product development lifecycle through extensive design and engineering expertise.

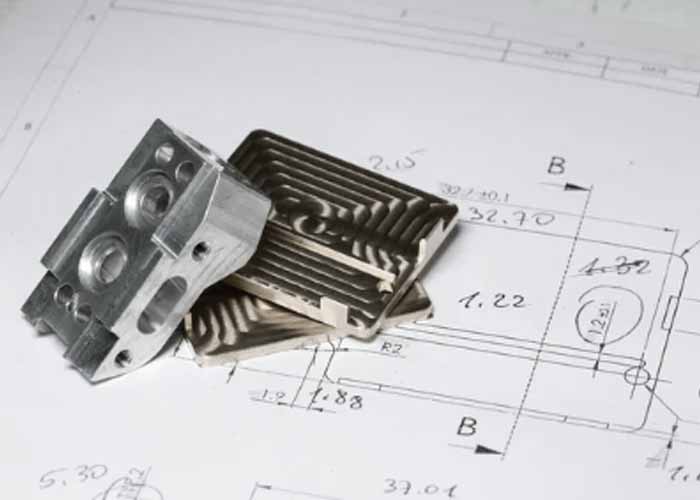

Our design team delivers highly accurate 2-D drafting and 3-D modeling as well as conversion of designs from older software. Each project is managed using a proven methodology that ensures requirements and budgetary targets are met.

SEATHER's Area of Expertise

The Seather team has expertise in multiple CAD packages, giving customers convenience and choice in the completion of design and modeling projects. Seather specializes in CAD products, including Autodesk, but also utilizes UG, SOLIDWORKS and ProE to meet specific requirements.

Design

CAD design services help organizations take ideas from concept to final product. By offloading engineering design works, organizations can save money, reduce lead times and allow in-house product development teams to focus on other business requirements. Our engineers have the experience to drive any project to successful completion.

Modeling and Drawing

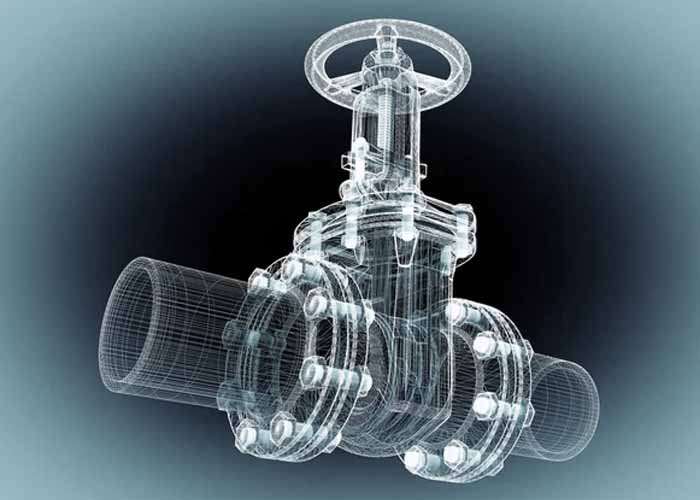

Many design teams are adopting a model-based definition, using 3-D models that incorporate engineering information and other product details. Seather provides 3-D modeling services as well as traditional 2-D drawings. We utilize the Siemens Teamcenter PLM tool for configuration control, review and signoff.

Reverse Engineering

Reverse engineering refers to the analysis of an existing part to capture dimensions for the development of a 3-D CAD model. Modern 3-D scanning tools allow designers to collect millions of data points with far less effort. Seather’s design experts then use sophisticated CAD software to develop a highly accurate 3-D model.

Geometric Dimensioning and Tolerancing (GD&T)

Variations in manufacturing processes cause product parts to differ in dimension from the original CAD model. GD&T is a highly accurate method of measuring allowable variations with product assemblies. Seather’s GD&T services enable engineers to understand how a part will behave within the assembly and provide the data manufacturers need to control variations.

Model Checking

Today’s CAD tools enable engineers to check models for compliance with company standards and design guidelines. However, model checking often falls to a design manager who must verify the work of multiple product developers. Seather offers these services to maximize CAD data quality while accelerating the design cycle.

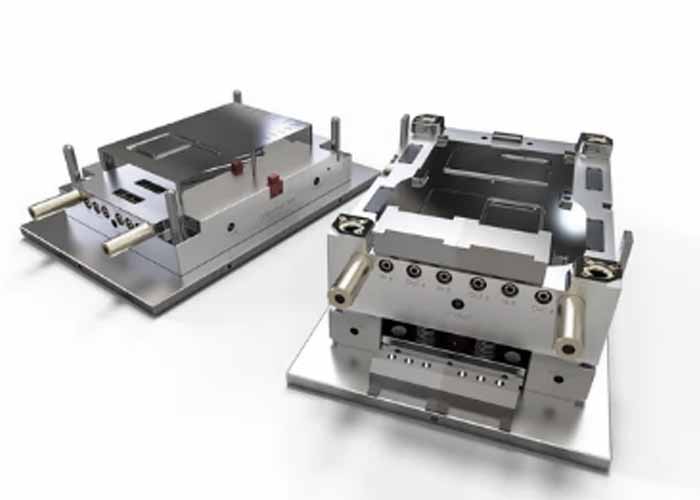

Gauge and Fixturing

Lightweight yet highly accurate gauges and fixtures can be developed using CAD design tools. Seather applies GD&T techniques to design gauges and fixturing that meet the stringent requirements of aerospace, automotive and other industries. We also leverage our knowledge and experience to evaluate existing gauges and fixturing.

Get Your CAD Design & 3D Drawings Here

in 4 Simple Steps

Design Analysis

We will discuss all drawings or ideas of design, then our team will offer the best solution for customer.

01

Design & Modeling

After checking the dimensions and details with customers, our team help new product design and modeling.

02

Customer Confirmation

Once finished the drawings, we send to customer for confirmation. And modify if necessary.

03

Design Finish

After checking the drawing design is not problem, we will send customer the final design drawings. This step will be very fast.

04

More Manufacturing & Engineering Services

We manufacture and supply customized products and provide surface treatment services according to customer specifications and industry standards. We are an efficient and cost-effective one-stop solution provider with the scale and capability to deliver integrated services.

Engineering Consulting

All engineers team are skilled in the design, optimization and validation of your concepts, prototypes and next generation products and systems.

CNC Machining Service

Custom cnc machining parts in nickel alloy and stainless steel delivery in as fast as 3 days.

Metal Fabrication Service

SEATHER’s custom sheet metal fabrication services offer a fast and cost-effective solution for your projects.

Sourcing & Supply

Highly experienced at managing complex supply chains on behalf of customers. Specializes in metal annual contracts and blanket orders.

CAD Design & 3D Modeling Services FAQS

AutoCAD is software for 2D and 3D computer-aided design.

Developed by Autodesk, AutoCAD is a commercial software application first released in 1992.

It is becoming more and more popular in modern days. Designers and engineers can use it for dealing with products more efficiently.

In alloy parts design and manufacturing field, it is widely used.

The Seather team has expertise in multiple CAD packages, giving customers convenience and choice in the completion of design and modeling projects. Seather specializes in CAD products, including Autodesk, but also utilizes UG, SOLIDWORKS and ProE to meet specific requirements.

SolidWorks is a powerful design and analysis program software. If you need some rudimentary 3D modeling, SolidWorks, like most professional design software, is much more tool than you need.

It is becoming more and more popular in modern days. Designers and engineers can use it for dealing with products more efficiently.

Ready to Get Started?

Contact us today and we’ll put together a quote tailored to your needs.