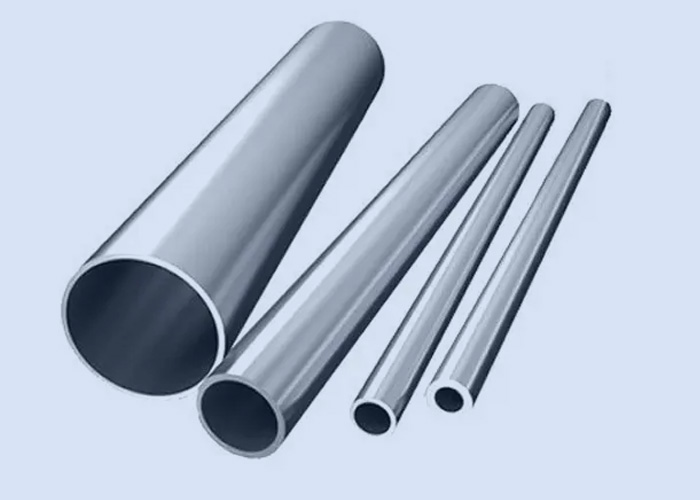

Nickel Based Alloys Seamless Pipes

As a leading China nickel based alloys seamless pipes supplier, SEATHER manufactures and produces different sizes and grades of nickel based alloys seamless pipes.

The nickel based alloys seamless pipes are recognized for their great properties high strength, excellent surface finish, and cost-effectiveness.

Seamless nickel based alloy pipes are excellent for heat exchangers in the chemical processing and nuclear industries. It is useful in high-temperature aircraft systems, in steam generator tubing, in nuclear power industry, and in oil and gas extraction programmes where corrosion, pressure and temperature resistant are required.

Whatever size at whatever tight tolerance of nickel based alloys seamless pipes you demand, SEATHER here is sure to have it!

| Form | Seamless |

| Application | Chemical plant, petro-chemical plant, pulp & paper mill, food & beverage plant, oil & gas industry |

| Outer Diameter (mm) | 0.6-1000mm or according to customer’s requirement |

| Wall Thickness (mm) | 0.05-20.0mm or according to customer’s requirement |

| Length | 3 meters and 6 meters or customer’s requirement |

| Standard | ASTM, ASME, EN, JIS, DIN, GB/T, etc |

| Process Method | Cold Drawn or Cold Rolled |

| Price Item | EXW, FCA, FOB, CFR, CIF, DDU or as negotiation |

| Payment | Our company accepts normally Paypal, T/T, and L/C payments. Call or email us if you need to use any new payment procedures |

| Delivery Time | It depends on your tubes order total quantity and stock of these mother origin materials. Usually from the start of the order to the completion of production is about 3-4 weeks |

| Quality Requirement | Mill test certificate will be offered with shipment, the third party inspection is available |

| Main Markets | Europe, North America, Middle East, Southeast Asia |

| Machanical Test | Tension test, flaring test, flattening test, hardness test, hydraulic test, etc. |

| Metal Test | High or low temperature impact test, metallographic analysis |

| Chemical Analysis | As tubes standard |

Our SEATHER professional team are experienced at tubes packaging to assure no any damages of products during transportation.

- Standard Export Packaging;

- In bundles with waterproof material, in wooden cases;

- Customized packaging as your request (Logo or other contents accepted to be printed on the pipes packaging);

- Other special packaging will be designed as customer’s request;

- Shipping port: Shanghai, Ningbo or as your request.

Nickel Based Alloys Seamless Pipes Materials & Grades

Nickel based alloys are a group of alloys that contain nickel as the primary component. These alloys are known for their high resistance to corrosion, high temperature resistance, and high strength. They are widely used in various industries, including chemical processing, oil and gas, aerospace, and power generation.

Some of the common nickel based alloys used in seamless pipes are:

- 600 (UNS N06600): This is a nickel-chromium-iron alloy that is known for its high resistance to corrosion and heat.

- 625 (UNS N06625): This is a nickel-chromium-molybdenum alloy that is known for its high strength and corrosion resistance, especially in harsh environments.

- 800 (UNS N08800): This is a nickel-iron-chromium alloy that is known for its high temperature resistance and excellent resistance to corrosion.

- 825 (UNS N08825): This is a nickel-iron-chromium-molybdenum alloy that is known for its high resistance to corrosion and excellent toughness.

- C-276 (UNS N10276): This is a nickel-molybdenum-chromium alloy that is known for its excellent resistance to corrosion in harsh environments.

These are just a few examples of nickel based alloys that are commonly used in seamless pipes. The specific grade of nickel-based alloy to be used depends on the specific requirements of the application and the operating conditions it will be subjected to.

For more information about nickel alloy seamless pipes, contact our expert team now!

Nickel Based Alloys Seamless Pipes Production Process?

Most people don’t know how the nickel alloy seamless pipe is made, instead, they always see a lot of nickel alloy seamless tube in plant or industrial field, but the truth is making nickel alloy seamless pipes is not easy than you imagined.

Basically, there are following steps for nickel alloy seamless tube making at SEATHER:

That’s all the steps in left infographics for how the nickel alloy seamless pipe was made, contact our team now!

Nickel Based Alloys Seamless Pipes Formula & Drawing

Formula: m = (OD – THK) × THK (mm) × L (m) × ρ (g/cm³) × π ÷ 1000

OD = Outside Diameter, THK = Wall Thickness, L = Length

ρ = Density, π = 3.1415926…

Your Reliable Nickel Based Alloys Seamless Pipes Manufacturer In China

Nickel Based Alloys Seamless Pipes: The Ultimate Guide

When you choose to buy nickel based alloy seamless pipes, there have some important points we need to know before we get started.

What are Nickel Based Alloys Seamless Pipes?

Nickel alloy seamless pipes refer to the types of alloy pipes with high strength and certain oxidation and corrosion resistance at high temperatures of 650-1000 °C.

Nickel Based Alloys Seamless Pipes Applications

Nickel based alloy seamless pipes are used in many fields, such as:

- Ocean: marine structures in the marine environment, seawater desalination, seawater aquaculture, seawater heat exchange, etc.

- Environmental protection: flue gas desulfurization device for thermal power generation, wastewater treatment, etc.

- Energy: atomic power generation, comprehensive utilization of coal, ocean tide power generation, etc.

- Petrochemical: oil refining, chemical and chemical equipment, etc.

- Food Industry: salt making, soy sauce brewing, etc.

In many of the above applications, ordinary stainless steel 304 seamless pipe is incompetent. In these special fields, special duplex stainless steel is indispensable and irreplaceable.

In recent years, with the rapid development of the economy and the continuous improvement of the level of the industrial field, more and more projects have chosen nickel alloy seamless tubes for use.

Features of Nickel Based Alloys Seamless Pipes

- Excellent oxidation resistance at high temperatures

- Good carbonation resistance

- Good oxidation resistance in sulfur-containing atmosphere

- Good mechanical properties at room and high temperatures

What are Nickel Based Alloys Seamless Pipes surface treatment?

Nickel based alloys seamless pipes are usually subjected to surface treatments to improve their properties and performance in various applications.

Some common surface treatments include:

- Polishing: This process is performed to produce a smooth, reflective surface finish.

- Annealing: This is a heat treatment process used to soften the pipes, improve their ductility, and reduce the hardness.

- Pickling: This process is used to remove surface impurities, such as oxide scales, rust, and other contaminants, using an acidic solution.

- Passivation: This process is used to improve the corrosion resistance of the pipes by creating an oxide layer on their surface.

- Electroplating: This process is used to deposit a layer of metal on the surface of the pipes for improved corrosion resistance and improved appearance.

- Sand Blasting: This process is used to produce a rough surface finish for improved adhesion for painting and other coatings.

The choice of surface treatment depends on the intended application of the pipes and the desired properties.

Key Considerations When Buying Nickel Based Alloys Seamless Pipes

When buying nickel based alloy seamless pipes, it is important to consider the following factors:

- Chemical composition: The chemical composition of the nickel-based alloy should meet industry standards and should be suitable for the intended application.

- Manufacture process: The manufacture process should be of high quality and should follow industry standards. Seamless pipes are preferred over welded pipes as they are stronger and have better corrosion resistance.

- Dimensions: The dimensions of the pipe, such as the outer diameter, wall thickness, and length, should meet the specifications required for the intended application.

- Surface finish: The surface finish of the pipe should be smooth and free from defects to ensure a uniform flow of the fluid or gas being transported.

- Mechanical properties: The mechanical properties of the pipe, such as its tensile strength, yield strength, and elongation, should meet the requirements of the intended application.

- Corrosion resistance: The corrosion resistance of the nickel-based alloy should be suitable for the intended application, and should meet industry standards.

- Price: The price of the nickel-based alloy seamless pipe should be competitive, and it should provide good value for money.

- Availability: The nickel-based alloy seamless pipe should be readily available in the required quantity, and the lead time for delivery should be reasonable.

- Certification: The nickel-based alloy seamless pipe should be certified to industry standards, such as ASTM, ASME, or EN, to ensure its quality and performance.

- Supplier: The supplier should be reputable, experienced, and knowledgeable about nickel-based alloys and seamless pipes, and should provide good after-sales support.

Looking For A Trust Nickel Based Alloys Seamless Pipes Manufacturer?

Contact us today and we’ll put together a quote tailored to your needs.