Custom Flanges

Custom flanges are the interconnected parts between the shafts, which are used for the connection between the pipe ends.

Seather provides custom flange templates for you to modify to your liking to get a better understanding of your project application.

Additionally, drawings for approval can be requested prior to actual manufacturing, provided an order already stands.

From raw materials forgings to finished custom flanges, Seather here is sure to help it!

Your Trusted Custom Flanges Manufacturer In China

Custom flanges fabrication is one of our core capabilities. Fabricating stainless steel and nickel based alloy flanges, our projects consist of large capital projects with thousands of tube sheets, as well as routine maintenance and one flange orders.

Our factories and fabrication facilities are filled with highly skilled craftsmen, fitters, fabricators, welders with excellent safety and quality performance records. We take great pride in not only meeting, but exceeding our customers’ expectations in all areas, including performance, design, logistics, schedule, delivery and cost.

| Product Name | Custom Flanges |

| Raw Materials | Different grade of titanium, nickel based alloy, duplex and super duplex stainless steel for custom pipe spool production, such as: Ti Gr1, Gr2, alloy 600, 625, 690, 800, 825, 800H, C-22, C-276, 400, Alloy 20, Duplex 2205, Super Duplex 2507, 904L, S31254, etc. |

| Size | OD40-10000MM, Thickness from 5mm-1100mm; Customized or according to your drawing |

| Samples | Sample available |

| Tolerance | +/-5mm to +/-0.005mm |

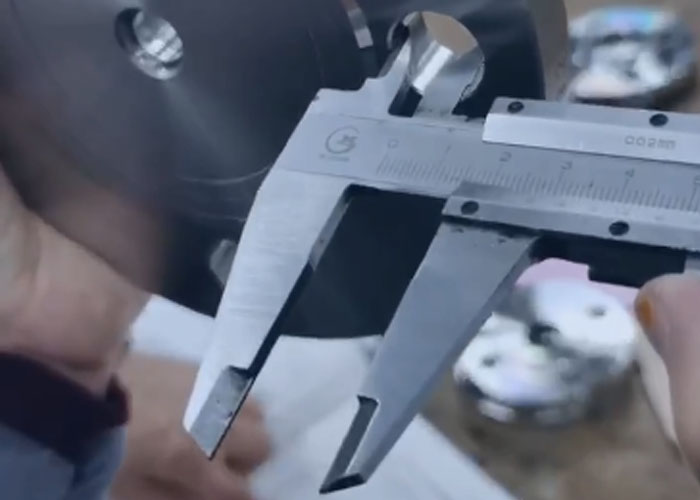

| Testing Equipment | CMM; Tool microscope; multi-joint arm; Automatic height gauge; Manual height gauge; Dial gauge; Marble platform; Roughness measurement |

| Logo | Custom logo available |

| Surface Treatment | Anodizing, Passivation, Polishing, Plating, Painting, Black Oxide, Powder Coating, Brushing, Heat Treatment, Surface Phosphating, Hot Dip Galvanizing, More Surface Treatment, etc. |

| Color | Silver, black, gold, red, green, blue, purple, etc |

| File Formats | UG, SolidWorks, Pro/E, AutoCAD (DXF, DWG), PDF, TIF, JPG, etc |

| Services | OEM/ODM, Engineering&Design Consulting, Assembly, Finishing, Materials Sourcing, Custom Packaging Services, etc |

| Quality System | ISO9001, SGS, TUV |

Special flanges and custom tube sheets and custom forgings can be designed to meet any number of unique specifications and standards.

Some common classifications for custom flanges include:

- AWWA, the American Water Works Association

- ASME, the American Society of Mechanical Engineers

- ANSI, the American National Standards Institute

- CL 125 lightweight

- Tube turns

- Large industry standard

- Metric system flanges

- Inner packaging: plastic wrap, bubble bag, PE foam, EPE cotton, PP bag etc;

- Outer packaging: carton box, wooden case, wooden pallets etc;

- Customized packaging as your request (Logo or other contents accepted to be printed on the custom flanges outside packaging);

- Other special packaging will be designed as customer’s request;

- Shipping port: Shanghai, Ningbo or as your request.

Custom Flanges Materials & Grades

| MATERIALS | GRADES |

| Stainless Steels | Austenite steel 321, 316Ti, 316L, 304L, 304, 309S, 310S, 347, 317L, Precipitation Hardening 17-4, 17-7, Duplex and Super Duplex stainless steel 2205, 2507, F53, 2101, 2304, Special stainless steel 904L, S31254, 1.4529, etc. |

| Nickel Based Alloys | Alloy B, B-2, B-3, C-22, C-276, C-2000; Alloy 800, 800H. 800HT, 825, 925, A-286, 330; Alloy 600, 601, 625, 690, 718, X-750; Alloy 400, K-500; |

For more raw materials information about custom flanges, contact SEATHER expert team now!

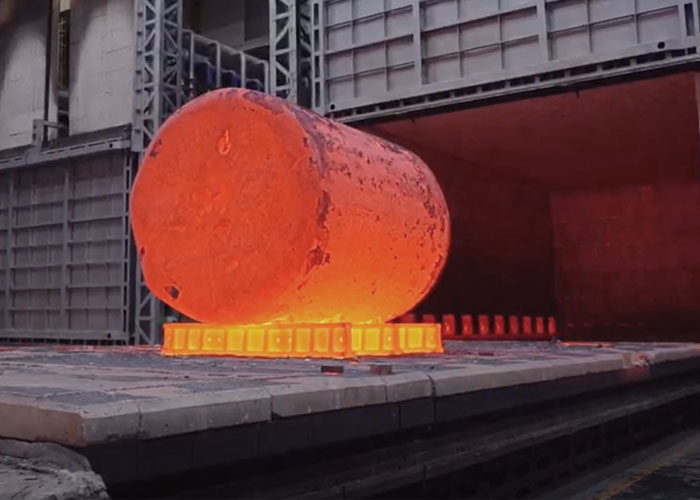

Custom Flanges Fabrication Techniques

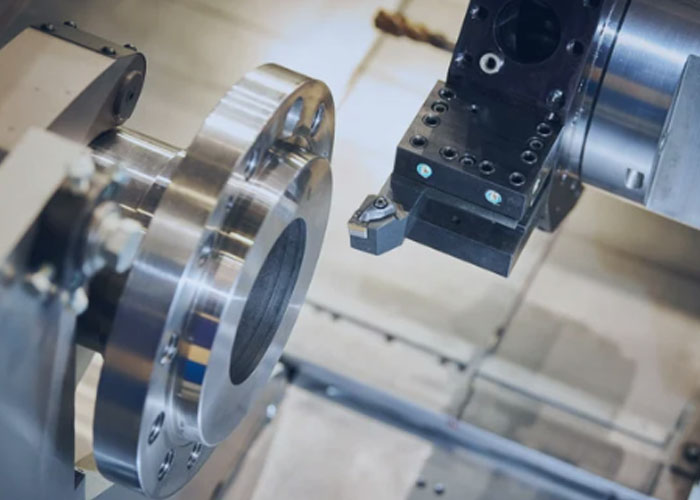

Custom flange design and production is largely automated these days with computer software (like CAD) performing the calculations and the flange drilling done on computer numerical control (CNC) machines.

Technical: Forged, Cutting, Machining, Inspection, Packaging

Heat Treatment: Normalizing, Annealing, Quenching, Tempering

Types&Tolerance: The flange shapes include round, oval, square, inclined and special ones, with the hole dimension accuracy to 0.01mm, hole wall roughness Ra0.6, and the tube plate’s sealing side roughness Ra0.4.

Why Choose SEATHER to Customize Your Custom Flanges

Custom Flanges Drawing Design

Custom Flanges Machining

Custom Flanges Inspection

SEATHER has been a leading nickel alloys and stainless steel suppliers in China thanks to its robust production capabilities, fast delivery time, and responsive enginnering support 24/7.

We produce nickel alloys and stainless steel materials, components, and complete assemblies involving single or combinative processes such as CNC machining, custom metal fabrication, forging, welding, etc. Our products are applied to a variety of industries serving a wide range of purposes, such as automotive, machinery, rail transit, power & energy, shipping and bridge, infrastructure, oil & gas, aerospace, heat exchangers, etc.

We have been dedicating to provide first-class quality nickel alloys and stainless steels products and services consistently to meet customers increasingly rising and specialized demands.

Manufacturing Services & Powerful Capabilities

Our cost effective precision metal machining for flanges include planing, cutting, milling, drilling, grinding, and any other metal processing techniques.

Need An Expert To Manufacture Your Custom Flanges?

Custom Flanges: The Ultimate Guide

Regardless of custom sizing or specifications, the fundamental design of most custom flanges falls under six common styles created to close, connect, cover, or support pipes and pipe systems.

When you choose to buy custom made flanges, there have some important points we need to know before we get started.

What are Custom Flanges?

Custom flanges are made of custom alloy forgings and round plates.

As the name implies, do not have standards, they are non-standard parts and require buyers to provide detailed drawings.

Custom Flanges Applications

Custom stainless steel and nickel alloy flanges are used in many fields, such as:

- Oil&Gas industry

- Chemical processing

- Pollution & Waste

- Marine

- Power plants and nuclear power

- Food and beverage processing

- Piping system manufacturing

- Valves & Actuators

- Heating systems

- Welding products

Features of Custom Flanges

- Corrosion resistant

- High tensile strength

- Very durable

- Temperature resistant

- Easy formability and fabrication

- Low-maintenance

- Attractive appearance

- Environmentally friendly (recyclable)

What Are Custom Flanges Surface Treatment?

Surface treatment is one of the major part in whole production.

Different surface finish will be used for different custom flanges.

With methods including anodizing, passivation, brushing, polishing, blackened, plating, painting, powder coating, heat treatment, surface phosphating, hot dip galvanizing, surface treatment dacromet, etc.

Key Considerations When Buying Custom Flanges

When purchase the custom flanges from China manufacturer, you should know the standards, size, materials grades, production process, drawings details, etc.

Below Is One Sample Purchasing Tips For Your Reference

- Standards: ASTM A240

- Material Grade: 904L stainless steel

- Size: As your drawing request

- Usage: Pressure vessel

- Production Process: CNC machined

- Tolerance: -1mm/+1mm

- Requirement On Properties: As your request

- Order Quantity, Delivery Time, Shipping Method, Place Of Delivery, Packaging Requirement, etc. should be considered.

Conclusion

Unquestionably, it is quite apparent that custom flanges revolves around numerous aspects, some of which we haven’t looked into here. But for now, at least you have the idea of what it takes to buy and install a functional flange that yields efficiency.

We are hopeful that this guide has been significantly helpful to you in many ways. And for that reason, it would be prudent if you also feel free to share it on your social media handles.

You know what, someone might also be looking for this kind of valuable information and you may be of considerable help too.

Otherwise, if you have any questions, recommendations, or concerns, you may also feel free to contact our expert team. For sure, we will gladly offer the necessary assistance.

More Resources

FAQS

These custom flanges types include:

- Slip-on Flanges: available in both standard and reduced sizes and both ring and hub style, manufactured to dimensions that will slide over a pipe with a snug fit

- Welding Neck Flanges: available in standard and reduced sizes, manufactured to the inside diameter dimensions of a pipe for attachment via welding

- Blind Flanges: available to seal both pipes and vessels

- Lap Joint Flanges: available in a range of sizes to pair with stub end fittings for easy dismantling

- Threaded (Screwed) Flanges: engineered to fit pipes with external threads for weld-free fits

- Socket Welding Flanges: designed with a socket fit and top weld for ideal inner flow in pipe systems

Looking For A Trust Custom Flanges Manufacturer?

Contact us today and we’ll put together a quote tailored to your needs.