This article discusses the differences between two nickel-based alloys, alloy 625 and alloy C276. Both alloys are composed of nickel, chromium, and molybdenum, providing them with outstanding corrosion resistance and strength.

However, there are distinct differences between the two 625 contains a higher chromium content, whereas C276 has a higher molybdenum content, leading to variations in their corrosion resistance under different environmental conditions.

Today, we will delve into a comprehensive comparison of these popular nickel-based alloys – 625 and C276 – highlighting their similarities, disparities, and optimal applications in various scenarios.

Let’s keep reading.

What is Alloy 625?

The alloy 625 is a nickel-based super alloy that contains a high amount of nickel concentration, far more than any of its other grades. It has high strength and high resistivity even at extreme temperatures. It has been shown to be very resistant to corrosion and oxidation. These specific properties make it very useful in marine and nuclear environments.

Alloy 625 also referred to as the UNS N06625, W.Nr. 2.4856 refers to strong solution that has been strengthen by the presence on nickel making it have a high resistance to corrosion, great tensile strength, high oxidation and excellent fatigue properties.

Properties of this alloy 625 make it an excellent product for use in the manufacture of chemical equipment’s, aerospace structural parts, and aero-engine parts.

Products Types of Alloy 625

- Alloy 625 Custom Ring

- Alloy 625 Pipe Spool

- Alloy 625 Custom Flange

- Alloy 625 Round Bar

- Alloy 625 Seamless Pipe

- Alloy 625 Welded Tube

- Alloy 625 Plate

- Alloy 625 Sheet

- Alloy 625 Strip

- Alloy 625 Wire

- Alloy 625 Foil

What is Alloy C276?

Nickel alloy C276 (also known as W.Nr. 2.4819) is a nickel-molybdenum-chromium wrought alloy material. It is also called UNS N10276 alloy.

Nickel alloy C276 is a type of nickel based alloys used in many industrial and commercial applications.

The alloy is resistant to pitting, crevice corrosion, and stress corrosion cracking.

Products Types of Alloy C276

- Alloy C276 Custom Ring

- Alloy C276 Pipe Spool

- Alloy C276 Custom Flange

- Alloy C276 Round Bar

- Alloy C276 Seamless Pipe

- Alloy C276 Welded Tube

- Alloy C276 Plate

- Alloy C276 Sheet

- Alloy C276 Strip

- Alloy C276 Wire

- Alloy C276 Foil

What are the Differences Between Alloy 625 and Alloy C276?

As you can see from their introduction and products types, alloy 625 and alloy C276 are very different. Depending on what you are looking for in your project, they each have benefits and drawbacks. For a side by side comparison, you breakdown the differences even further.

Chemical Composition

Corrosion Resistance

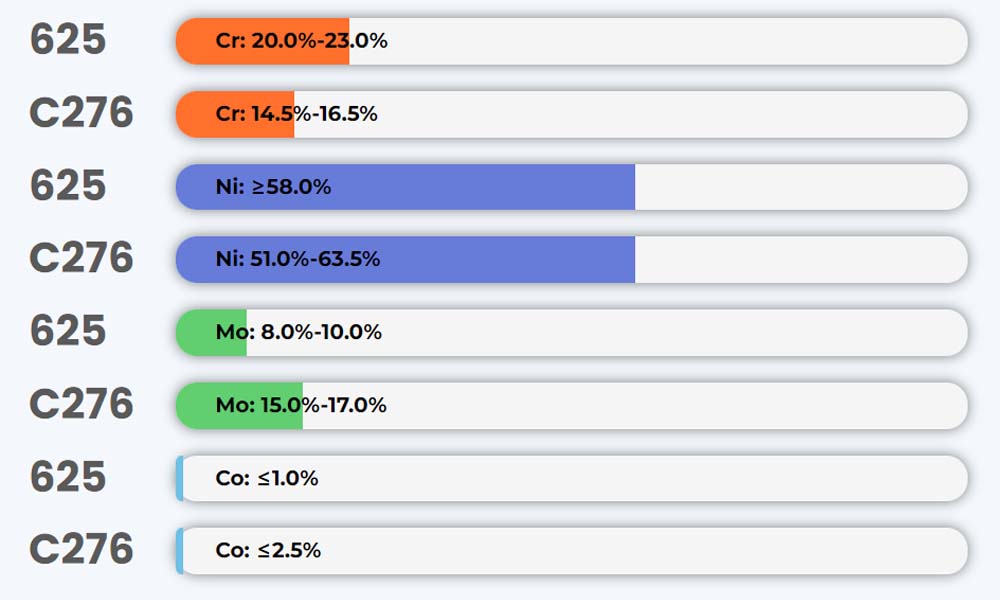

The nickel and iron content of 625 alloy and C276 alloy are very close. The main difference between them is chromium and molybdenum chemical elements.

625 has more chromium content than alloy C276, and chromium is shown as oxidation resistance in terms of corrosion resistance. This makes 625 has better corrosion resistance in oxidizing environments (such as concentrated sulfuric acid, nitric acid, etc.).

Mechanical Properties

Alloy 625 Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 135,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Alloy C276 Mechanical Properties

| Element | Yield Strength (0.2%Offset) | Melting Point | Density | Tensile Strength | Elongation |

| C276 | Psi – 52,000 , MPa – 355 | 1370 °C (2500 °F) | 8.89 g/cm3 | Psi – 1,15,000 , MPa – 790 | 40 % |

Applications

Alloy 625 Applications

- Aerospace

- Chemical Processing

- Heat Exchangers

- Construction

- Bridges

- Petrochemical Industry

- Ship Building

- Engineering

- General Structural Purposes

Alloy C276 Applications

- Chemical process industry

- Flue gas desulfurization units

- Pickling equipment in the steel industry

- Waste incineration plants

- Seawater desalination plants

- Flue gas scrubbing facilities

- Pharmaceuticals

- Heat exchangers

Main Standards

Alloy 625 Products Standards

- Seamless Pipe: ASTM B444, ASTM B829

- Welded Tube: ASTM B704, ASTM B751

- Welded Fittings: ASTM B366

- Round Rod&Bar: ASTM B446

- Forgings: ASTM B564

- Plate&Sheet, Strip and Foil: ASTM B443

Alloy C276 Products Standards

- Seamless Pipe: ASTM B622, ASTM B983

- Welded Tube: ASTM B626

- Welded Fittings: ASTM B366, ASTM B462

- Round Rod&Bar: ASTM B574

- Forgings: ASTM B564, ASTM B462

- Plate&Sheet, Strip and Foil: ASTM B575

Cost

The costs of 625 and C276 differ significantly.

Alloy 625 is generally more expensive than C276.

The higher cost of 625 can be attributed to its higher percentage of chromium and other alloying elements, which contribute to its exceptional corrosion resistance and strength properties.

On the other hand, alloy C276 offers excellent performance at a more affordable price point, making it a favorable option for certain applications where the highest level of corrosion resistance is not required, or cost considerations are a priority.

Therefore, the choice between the two alloys often depends on the specific requirements and budget constraints of the project or application at hand.

FAQs

What is the density of Alloy 625?

The alloy 625 has a density of 8.44 g/cm3, which makes it slightly heavier than other alloys such as copper alloy or aluminium alloy, but lighter than special stainless steel or titanium alloys.

What is the difference between 625 alloy and 718 alloy?

Alloy 625 possesses considerable amounts of nickel, chromium, and molybdenum making it not only strong at high temperatures but also resistant to corrosion, oxidation, and carburization. One of its most notable characteristics is its ability to prevent stress, pitting and crevice corrosion cracking even when exposed to chloride ions.

Alloy 718 is an age-hardened version of alloy 625. Aging (or precipitation hardening) produces precipitates in the molecular structure that pins the grains of the metal in place. As a result, materials usually become significantly stronger. In the case of this, 718 has exceptional strength with a yield strength that is about 2x’s stronger than 625.

What is the density of alloy C276?

Physical properties of alloy C276 alloy exhibit that it is a strong alloy with density 8.89 g/cm3.

Is alloy C276 resistance to hydrochloric acid?

At hydrochloric acid concentrations above about 5%, C276 alloy provides a quantum improvement over the normal stainless steels, and offers much greater resistance to higher concentrations of both acids than alloy 625.

Is Alloy C276 magnetic?

Grade C276 alloy is non-magnetic and has low magnetic permeability.

Are 625 Alloys Better Than C276 Alloys?

Both the 625 alloy and the C276 alloy exhibit commendable corrosion resistance.

625 is particularly well-suited for oxidizing environments.

On the other hand, alloy C276 is better suited for reducing environments.

Both alloys are solid solution strengthened alloys.

Conclusion

Grade 625 alloy and C276 alloy both exhibit excellent corrosion resistance, but their suitability in different environments sets them apart.

625 is better suited for oxidizing environments, while C276 excels in reducing environments.

Choosing the optimal material depends on the specific application requirements, which must be carefully evaluated before making a decision.

At Seather, we are equipped to manufacture alloy 625 and C276 related products tailored to your exact specifications. Contact our expert team today for your nickel alloys project.