Nickel-based superalloys show outstanding strength, stability, and corrosion resistance at high temperatures.

Superalloys are non-ferrous, and they get their strength from solid solution strengthening.

With a small amount of Nickel, these alloys are considered high-performance for many applications.

The design qualities of superalloys classify them, especially mechanical strength, toughness, and resistance to a variety of conditions that could normally destroy normal materials.

Nickel-based superalloys are typically utilized at temperatures above 540 °C (1000 °F); at these temperatures, regular steel and titanium alloys lose strength.

At this temperature, corrosion is also widespread in steels. Nickel-based superalloys maintain mechanical strength, surface stability, thermal creep deformation, and resistance to corrosion at high temperatures.

What are Nickel-based Superalloys?

Nickel-based superalloys are often composed of nickel, aluminum, or titanium.

Because of their good material qualities at high temperatures, these alloys are commonly utilized as turbine blades in jet engines and turbochargers.

Nickel-based superalloy shows excellent corrosion resistance at high temperatures compared to iron-based alloys.

Along with nickel, several other elements are added to make a superalloy.

It cannot be substituted in many applications due to its outstanding properties.

Nickel-based superalloys are widely used in aerospace, energy, chemical, and petroleum applications. It is one of the most important alloy in modern industry.

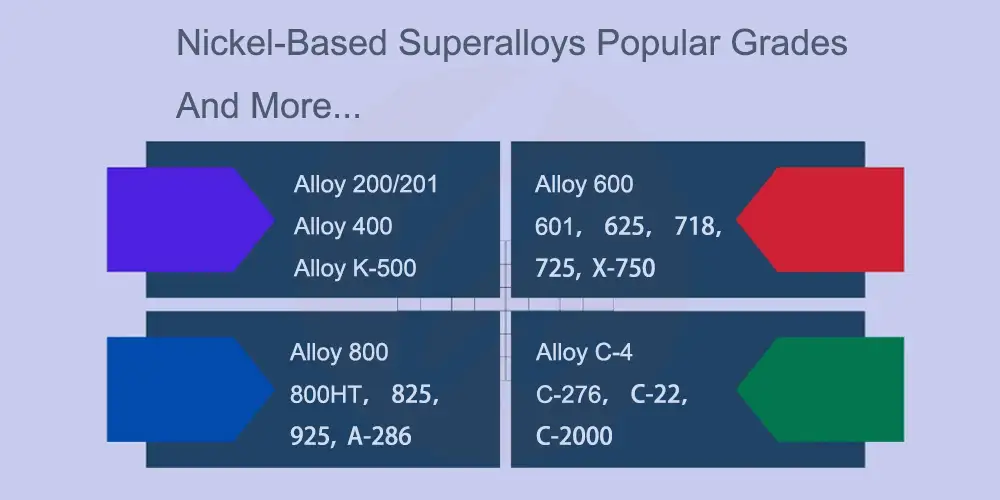

What are Nickel-based Superalloys Grades?

Alloy 600, 625, 718, X-750, 800, 825, C-276 and 400 are some examples of nickel-based superalloys grades.

Generally, every nickel based alloy contains some iron in its composition, usually more than 1%. Other elements found in some Inconel alloys are Cobalt, Molybdenum, Niobium, and Titanium.

Nickel-based Superalloys Chemical Compositions

The chemical composition of some of the most commonly used nickel-based superalloys is given in the following table:

Alloy Grades | Ni % | Cr % | Fe % | Co % | Mo % | Cu % | Ti % | Al % | Mn % | Others % |

600 | 72 | 14~17 | 6~10 | – | – | 0.5 | 0.3 | 0.3 | 1 | Si 0.50 |

625 | 58 | 20~23 | 5 Max | 1 Max | 8~10 | –

| 0.40 | 0.40 | Nb 3.15-4.15% | |

718 | 50~55 | 17~21 | balance | 1 Max | 2.8~3.3 | 0.3 | 0.65~1.15 | 0.2~0.8 | Nb 4.75~5.5 | |

800 | 30~35 | 19~23 | 39.5 Max | – | – | 0.75 | 0.15~0.6 | 0.15~0.6 | 1.5 | C 0.08 Max, |

825 | 38~46 | 19.5~23.5 | 22 | – | 2.5~3.5 | 1.5~3.0 | 0.6~1.2 | 0.2 Max | 1 Max | Si 0.5 |

400 | 63~70 | – | 2.5 | 1.0 | – | 28~34 | – | – | 2.0 | Si 0.5, C 0.3, S 0.024 |

K-500 | 63~70 | – | 2 | – | – | 27~33 | 0.35~0.85 | 2.3~3.15 | 1.5 | Si 0.5, C 0.25, S 0.01 |

C-276

| 57 | 14.5~16.5 | 4~7 | 2.5 Max | 15~17 | – | – | – | 1 Max | W 3.0~4.5, V 0.35, P 0.04 S 0.03 |

C-22

| 56 | 20~22.5 | 2~6 | 2.5 Max | 12.5~14.5 | – | 0.6~1.2 | 0.2 | 0.5 | W 2.5~3.5, V 0.35, P 0.02 S 0.02 |

B-2

| 65~70 | 1 | 2 | 1 | 26~30 | – | – | – | 1 | Si 0.1, C 0.02 , P 0.04 S 0.03 |

Nickel-based Superalloys Density

The density is described by the amount of Mass per unit volume and calculated by this formula:

Density (p) = Mass (m)/ Volume (v)

There are different grades of nickel-based superalloy, and the densities are also different for each step.

Furthermore, the density ranges from 8360 to 8840 Kg/m3.

What Is Nickel-based Superalloys Application?

Engine components

Nickel-based superalloys are ideal for high-speed and high-friction applications that create heat due to their superior heat resistance. The material has made its way into the production of aero-engine parts and aerospace equipment accessories.

Combustion chambers

Nickel-based superalloys are best for combustion chambers because extremely high temperatures are predicted in combustion vessels.

Turbines powered by steam

Steam turbine power plants, like combustion equipment, demand temperature-resistant materials like nickel-based superalloys to keep the system preserved and undamaged.

How To Manufacture Nickel-based Superalloys?

Generally, the casting method is used in the manufacturing of superalloys.

Directionally solidified casting and single-crystal casting are two types of casting used to manufacture superalloys.

Directly solidified casting entails casting the metal and carefully cooling it to control the formation of the grain structure. Single-crystal casting operates in the same way.

However, the temperature is considerably more tightly controlled, and any deviation will result in a failure cast.

How To Choose Right Nickel-based Superalloys For Your Project?

Before choosing the right nickel-based superalloy for your project, you must know about your application’s requirements, specifications, and temperature conditions.

If you are in doubt, contact us our team of experts will deeply observe and select the perfect grade for your nickel-based superalloy project.

Conclusion

All nickel-based superalloys play a very important role in the morden industry due to their excellent properties and variety of grades.

These alloys perform better in high temperatures and harsh conditions due to the high concentration of nickel.

At SEATHER, we are experts in the field of nickel based superalloys manufacturing. As such, we offer a variety of services to ensure your project is formed to your exact requirements. Contact us today.